David Eszenyi, Commercial Director of engine remanufacturer Ivor Searle, provides some handy tips for installing a replacement Duratorq unit.

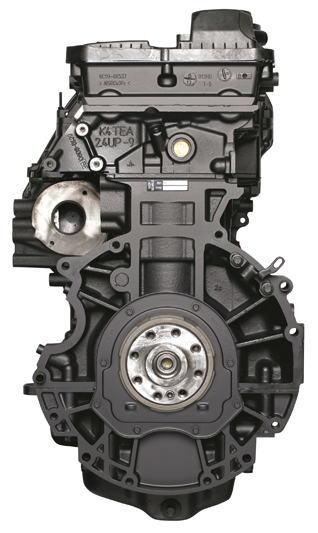

The 2.2 and 2.4L variants of the Ford Duratorq TDCi unit fitted to the Transit is the most common engine remanufactured by Ivor Searle. Also found in the Land Rover Defender, these engines are prone to failure due to combustion issues that lead to thermal detonation, loss of compression, and piston failure, resulting in damage throughout the powertrain. In the worst instances, we have seen pistons that have completely melted.

We are also aware of Duratorq failures that have occurred due to faulty or incorrectly fitted injectors or high- pressure pumps, faults in the common rail fuel rail pressure sensor, or faults in the ECU software.

Duratorq pre-installation

With these faults in mind, it’s important to ensure that the cause of the original unit’s failure has been identified and remedied prior to installing a remanufactured Duratorq engine. It’s also essential that the engine management ECU is interrogated with appropriate diagnostic equipment and up-to-date software. We recommend that the following steps are taken:

- Investigate and rectify the cause of any fault codes stored in the ECU before starting the replacement engine

- Remove the injectors from the old engine, and transfer to the same cylinder on the replacement unit (i.e. injector from No. 4 cylinder on old engine fitted to No 4. cylinder on replacement)

- Clear all stored ECU fault codes

- Program the ECU with the base line requirements (including injectors).

- The ECU should then be re- programmed with the latest OEM software version

Engine oil

Remanufactured engines are supplied without engine oil. So, before turning the engine, it is critical that the replacement unit is filled with oil that meets the original manufacturer’s specifications and filled to the correct level.

Cooling system

Before fitting the replacement reman engine, we recommend that the cooling system is thoroughly checked, cleaned, and, if required, that system components are replaced.

Breather system

Where parts require transferring from the old engine to the new one, it is essential that the items incorporating crankcase breathers are thoroughly cleaned or replaced with new parts, including the rocker or cam covers. In addition, all rubber breather pipes should be replaced, and any electronic or vacuum control valves should be checked for correct operation. If the breather system is blocked or restricted, the crankcase can become pressurised. As a result, the efficiency of the oil control rings and valve stem oil seals is reduced, and problems with high oil consumption could occur.

Poor crankcase ventilation will also prevent the engine from disposing of impurities such as water vapour and acids, which are formed as a by-product of combustion; these will reduce the life expectancy of the lubricating oil, causing sludging and premature engine wear. The gases that build up in a pressurised crankcase will attempt to ventilate wherever possible, usually via the dipstick, rocker or cam cover gaskets and engine oil seals.

Air intake manifold

This must be thoroughly cleaned and checked for cracks, corrosion and distortion. The intake manifold gasket must be fitted correctly; the securing nuts, bolts or studs must be tightened in the correct order and to the correct torque. Bolt and stud threads should be treated with a sealing compound to prevent oil or coolant leakage.

Many air intake manifolds are fitted with butterfly or other variable valves, and these should be checked for wear and serviceability before re-fitting. If the original engine failure resulted in engine debris entering the induction system, then it is essential that all traces of debris are removed to prevent this being sucked back into the replacement engine, causing further damage.

Starting the engine

Check that the oil and coolant levels are correct before starting the engine. We also advise disabling the fuel or system, and turn the engine via the starter motor until the oil pressure indicator light goes out.

After running the engine, check the oil and temperature gauges. If there is low oil pressure, or the engine temperature is excessive, stop the engine immediately and check for possible causes. The new engine must not be left idling for prolonged periods. Such early life operation will create cylinder bore glazing and consequently excessive oil consumption. At the end of the test drive, ensure that the oil pressure and coolant temperatures are still at the correct levels, and check for oil, water and fuel leaks.