Adam Pearce, Product Manager at Parker Racor, talks CVW through the evolution of diesel engine systems and how this has affected fuel filtration technology.

When it comes to the effective and reliable filtration of diesel for HGVs, there are a number of challenges to negotiate. This has been the case since the first diesel engine, and has persisted through to modern-day common rail injection systems featuring ultra-small injection orifice diameters and uber-high pressures. In short, the common objective for filtration technology in every generation of diesel engine has been to improve system cleanliness and, in turn, boost engine reliability and reduce emissions.

When it comes to the effective and reliable filtration of diesel for HGVs, there are a number of challenges to negotiate. This has been the case since the first diesel engine, and has persisted through to modern-day common rail injection systems featuring ultra-small injection orifice diameters and uber-high pressures. In short, the common objective for filtration technology in every generation of diesel engine has been to improve system cleanliness and, in turn, boost engine reliability and reduce emissions.

Today, emissions have become one of the primary drivers of diesel engine development and thus fuel filtration. Although emissions regulations vary around the world, since the late 1990s, there have been dramatic cuts to the allowable quantities of NOx (nitrogen oxides) and PM (particulate matter) that can exit the exhaust. For instance, Euro VI only permits 0.4g/kWh of NOx and 0.01g/kWh of PM for heavy-duty diesel engines found in the truck and bus market. These limits have had a notable bearing on engine development, which has ultimately led to the latest high- pressure (>2,500 bar) fuel injection systems.

A further vital element in the successful development of effective filtration technology is fuel quality. Knowing the exact composition of common fuels is essential in designing the appropriate filters. With this thought in mind, Parker Racor leverages data from a global fuel survey that features over 900 fuel samples taken from 100 countries. The analysis concentrates on solids contamination, water, bio-content, inorganic content and cold characteristics.

With today’s fuel injection systems offering clearances of typically less than 3μm, it is easy to envisage the potential damage that contaminants can cause, which is why fuel cleanliness demands continue to escalate. The single 8-10μm diesel fuel filters of yesteryear would simply not be suitable for the truck and bus market in 2019. Any contamination that is allowed to permeate downstream can promote wear mechanisms such as abrasive flow wear, where particles rub against walls as sections narrow and flow accelerates, and abrasive contact wear, which begins when particles get trapped between moving components.

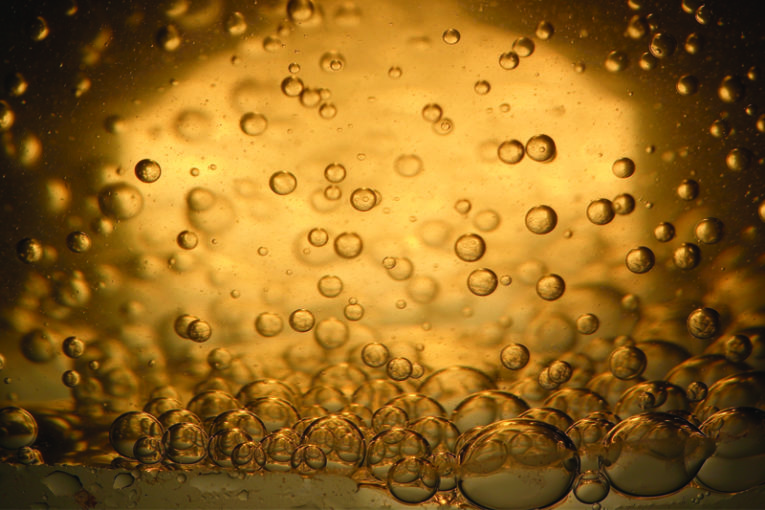

Overnight temperature changes with nearly empty fuel tanks are another common issue, as this scenario causes water to condense. Many cite water as an engine’s worst enemy, as it displaces the lubrication properties of diesel, which in turn damages injection components. In addition, iron oxide (rust) is a primary contributor to injector wear, while the development of algae or ‘diesel bug’ can block the fuel system and filter, compromising engine life.

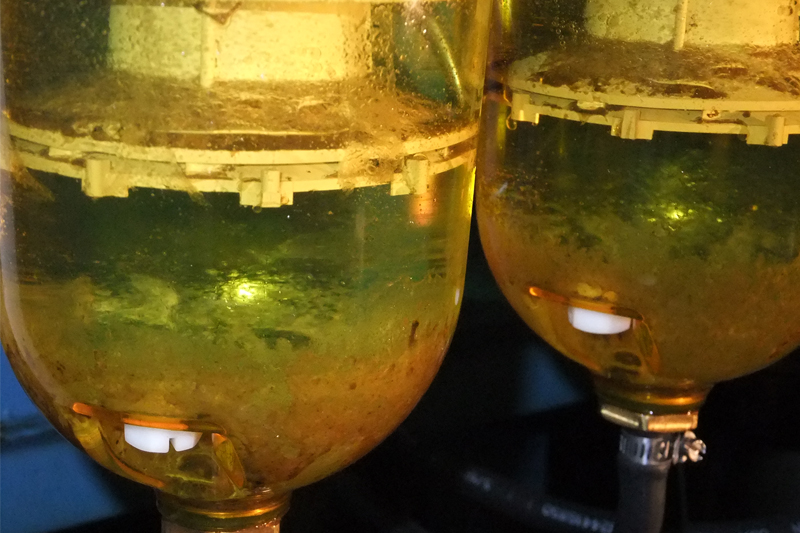

To avoid costly engine and fuel system component damage in the latest high- pressure common rail systems, advanced multi-stage filtration is recommended.

Among recent developments in this area is Racor’s new coalescing filtration media, which represents a technological step change in diesel fuel filtration. Unlike conventional barrier water separators, which separate water from fuel with a single hydrophobic barrier filter element, Aquabloc3D elements use three distinct stages to ensure only clean fuel passes to the engine. Purpose-designed to deal with increasingly sophisticated fuel, Aquabloc3D filters offer long service life.