For decades, FAG has been providing truck and axle manufacturers with OE components and systems. The brand, part of the Schaeffler Group, also develops complete repair solutions for the aftermarket, the latest of which is a unique product that makes hub bearing replacement much simpler. Here, the company provides some best practice advice for workshops.

Wheel bearing repairs are commonplace in the CV sector, with most truck and trailer axles fitted with two opposing single tapered rolling bearings (TRBs). The FAG SmartSet was designed specifically for the

aftermarket to reduce the problems caused by the tricky installation of traditional TRBs, such as extended downtime and an increased chance of fitting errors.

Each SmartSet box contains a pre-greased, preassembled and pre-positioned complete hub repair solution, plus a pressing tool and detailed instructions.

Wheel bearings are a safety-critical component, so to ensure technicians are prepared and able to conduct an efficient repair, Schaeffler has produced two‘tech tips’ which will help prevent premature failure; before looking at both of these, however, it is important to follow these steps:

■ Keep the workplace clean;

■ Use the recommended tools;

■ Check all the surrounding parts, such as hub and axle;

■ Observe the correct tightening torque;

■ Adhere to all installation instructions.

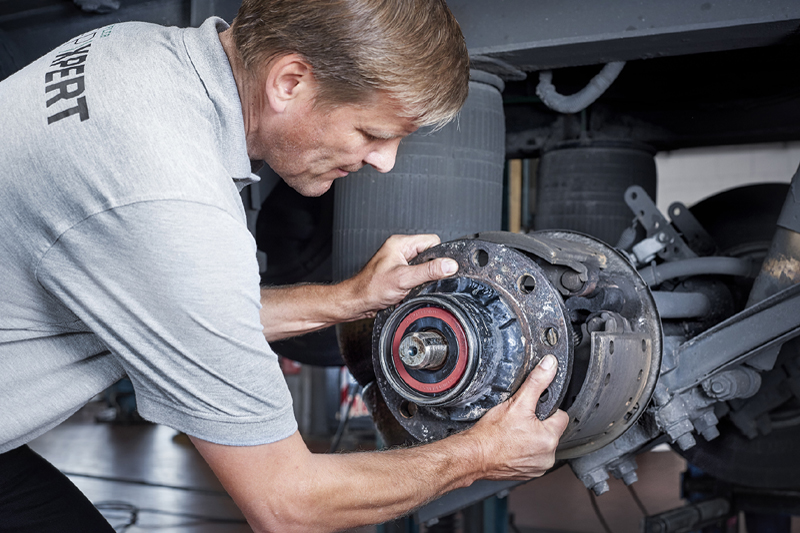

Best practice during hub removal

When removing the wheel hub, brake disc and drum it is very easy for dirt to contaminate standard TRBs. As a result of this, standard TRBs need to be removed, cleaned and refilled with grease. The wheel hub must also be cleaned and checked for ovality, and the rotary shaft seal must be replaced.

Also, every time the wheel hub is removed there is a danger that it can have a negative effect on the service life of standard TRBs: they can become contaminated; can be lubricated incorrectly, either with too much or too little grease or even with the wrong specification; the seal can be damaged, and it can be difficult to reposition the bearing.

According to Schaeffler, the FAG SmartSET effectively removes these potential pitfalls, as the bearings are sealed for life and cannot be contaminated. It is claimed that another added benefit is that installation times are reduced by up to 50% in comparison with fitting a standard TRB – saving as much as two hours’ labour cost.

Pre–lubricated

The FAG SmartSET can be used for both grease or oil-lubricated wheel bearing applications. The bearing unit itself is prefilled with grease, which acts as a start-up lubrication for the bearing. Once the startup phase has ended, however, the axle/hub oil takes over. To ensure that the right amount of lubrication has been applied, it is vital that the technician uses the correct oil filling level and specification.

The service and replacement intervals, according to each vehicle manufacturer, must also be followed. With 19 different versions already available, and 14 more on the way, covering not just trucks but also trailers (including BPW and Meritor), Schaeffler says the FAG SmartSET really is the smart solution.