Schaeffler details the continued push towards electrification in the commercial vehicle sector and how workshops need to prepare themselves in the not-too-distant future.

In the face of a global tightening of pollution and CO2 restrictions, Schaeffler has expanded its range of powertrain electrification solutions for commercial vehicles, another key contribution to meeting climate and sustainability targets.

“The commercial vehicle sector is facing major challenges,” says Matthias Zink, CEO Automotive Technologies at Schaeffler AG. “We are bringing our considerable systems expertise in the field of commercial vehicles for shaping how the world moves. The fact that we won two major contracts recently shows that we are on track to being a preferred technology partner for our customers in this sector.”

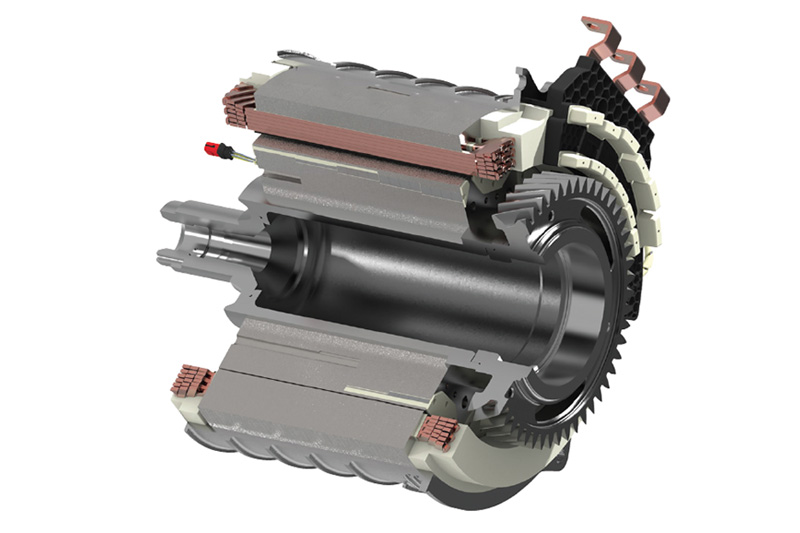

Electric motors and hybrid modules

Schaeffler has secured a volume production order to supply electric motors to a big-name subcontractor in the commercial vehicle sector, starting in 2023. The 800V motor, used in pairs in battery-powered vehicles, delivers a maximum continuous output of 180kW and generates a maximum torque of 950Nm.

It also features rod wave winding technology, an innovation that makes installation less complex and increases power density. The motor plays an important role in the electrification of commercial vehicles and thus contributes to a marked reduction in CO2 emissions.

Schaeffler has also secured a volume production order for hybrid modules. Featuring the highly efficient P1 architecture, these modules enable the recovery of braking energy. The energy recovered is then used to power on-board systems, especially new exhaust gas treatment systems, thereby helping vehicle fleets to meet NOx and CO2 reduction targets. The start of production is scheduled for 2024.

Dr. Jochen Schröder, President of the EMobility business division, comments: “We have positioned our electric mobility business very effectively. Schaeffler offers solutions for all powertrain electrification options, from 48V hybrid to plug-in hybrid to full electric. All development and production of our components and systems can take place in-house, which puts us in an ideal position to partner our customers in these diverse markets.”

Schaeffler drives responsibility

For the Schaeffler Group, sustainable success in business means being environmentally and socially responsible. Sustainability is a driving factor in the ongoing development of the global automotive and industrial supplier’s corporate strategy. It is also a fundamental part of the Roadmap 2025 blueprint for strengthening the group’s ability to realise future opportunities.