MEI presents its solution to fully sealing both ends of the short guide sleeve on replacement calipers, which can help reduce friction material wear. Here’s how the new design works, as well as some useful fitment advice.

Many calipers in the field have short guide sleeves that are not fully sealed. The guide sleeve is resistant to corrosion, but water and debris can still get between the sleeve and rubber bush, causing excessive wear or in some cases, restriction to sliding. As has been discussed in previous articles, a sliding system that is not free to move can cause the outboard pad to drag and increase the wear rate of the friction material. In severe cases, the residual dragging can cause elevated brake temperature.

The selling boot has a stainless steel insert, which comes pre-assembled on the short guide sleeve (Fig. 3). The first step is to assemble the guide sleeve bolt into the guide sleeve (fitting it later can be tricky, as the black rubber boot restricts the entrance); lubricate the sleeve with the grease provided and insert the short guide sleeve from the disc side.

With the sleeve inserted into the rubber bush, pinch the grey rubber boot between your finger and thumb, and stretch the bead into the groove of the metal ring on the end of the rubber bush (Fig.4).

When the boot is fully in place on the metal ring, it should look like Fig. 5. Make sure the bead is seated all the way round the metal ring. Following this, it’s time to fit the carrier.

Tighten the bolts to 180Nm +90° and ensure the carrier is firmly clamped in a vice at the side you are tightening. Be careful not to damage the black rubber boot with the 14mm hexagon key (Fig.6).

Make sure the long guide sleeve and end cap are fitted in the normal way and ensure the carrier remains in a position where the inner boots (green and grey) are compressed. Stretch the black boot onto the outer diameter of the short guide sleeve (Fig.7&8).

Next, offer up the green plastic cap so that it just locates in the end of the guide sleeve, but don’t push it into place just yet (Fig.9).

Slide the boot off the guide sleeve to make the bead drop into the groove in the green plastic cap (Fig.10).

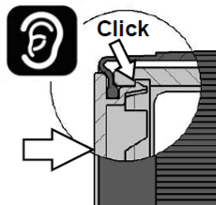

With the boot fully located all the way round the cap (Fig.11), push the cap squarely and firmly, ensuring that it clicks into place in the guide sleeve (Fig.12&13).

Calipers with a fully sealed short guide sleeve will be available from MEI Brakes in spring 2019. The design will enable MEI calipers to fit all applications that previously ran with an open sleeve only. Vehicles operating in all conditions should benefit from the longer service life of the short guide sleeve system with the fully sealed design.