With damaged panels comes the difficult task of repairing them. To help, Mirka lays out the best practice for panel repair so that commercial vehicle technicians can make a vehicle look brand new.

Replacing damaged panels can be a time-consuming job, and with businesses looking at reducing key-to-key times and not including the added expense of purchasing new panels into the cost of the overall job, repairing as opposed to replacing is becoming a mantra that they are living by.

Best practice:

First stage

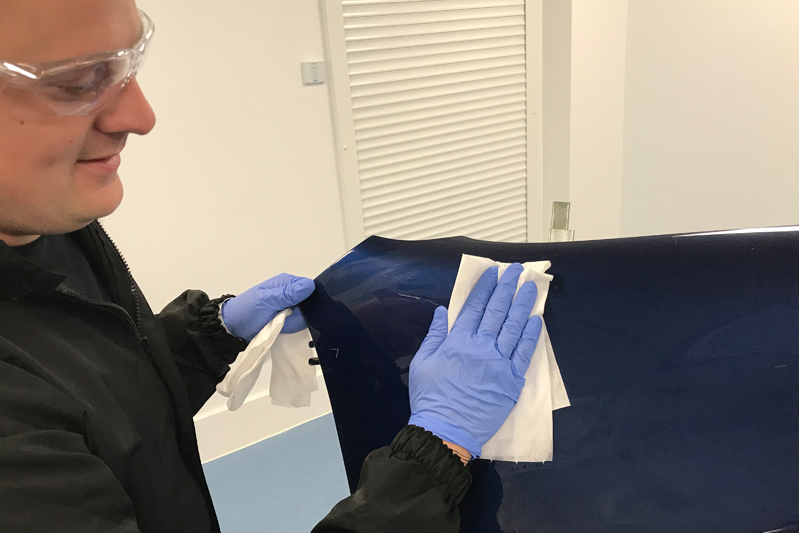

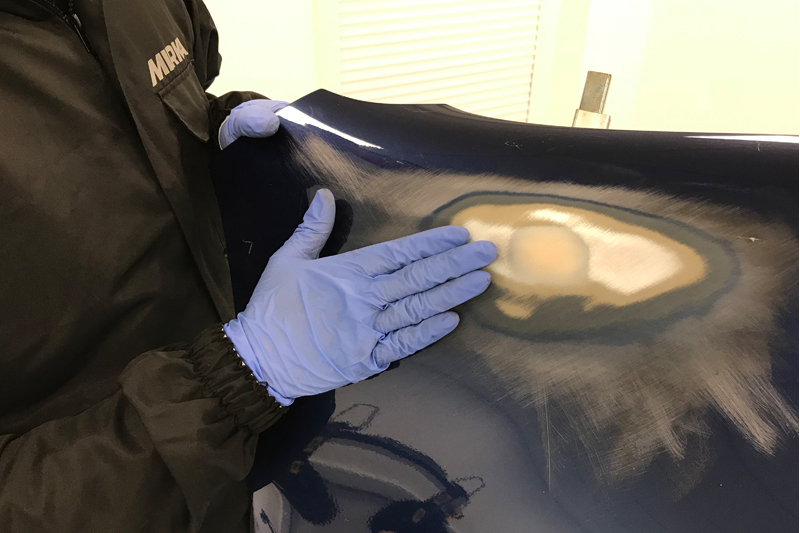

STEP ONE:

Action: Surface preparation is key. De-grease the surface prior to sanding.

Use: A water borne and a solvent degreaser.

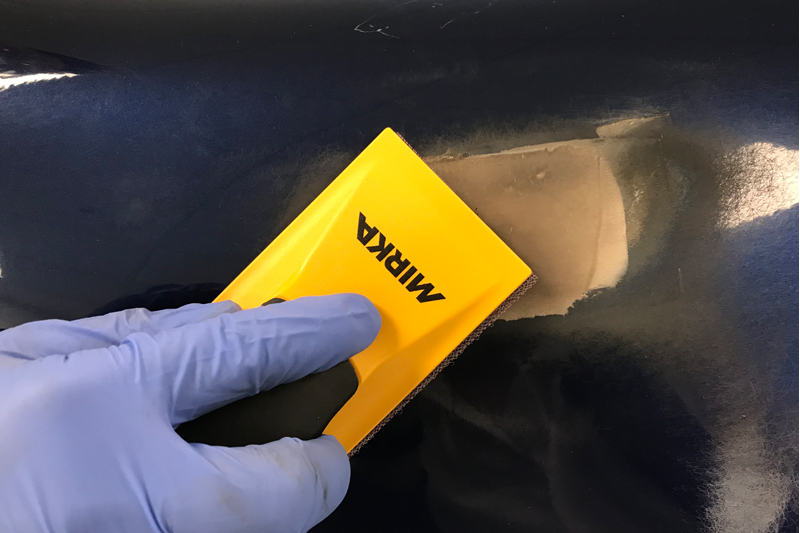

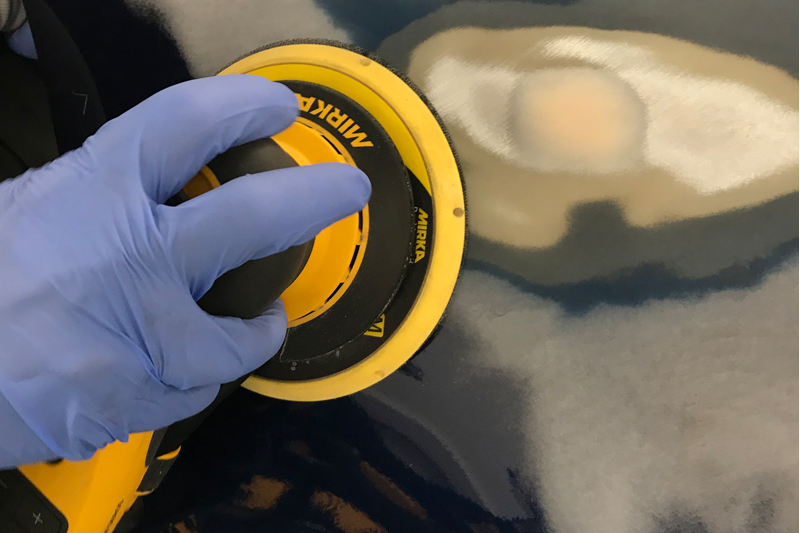

STEP TWO:

Action: Remove paint from the repair area and feather out the edges.

Use: P80 or P120 disc.

STEP THREE:

Action: Pre-clean the repair area and apply relevant filler.

STEP FOUR:

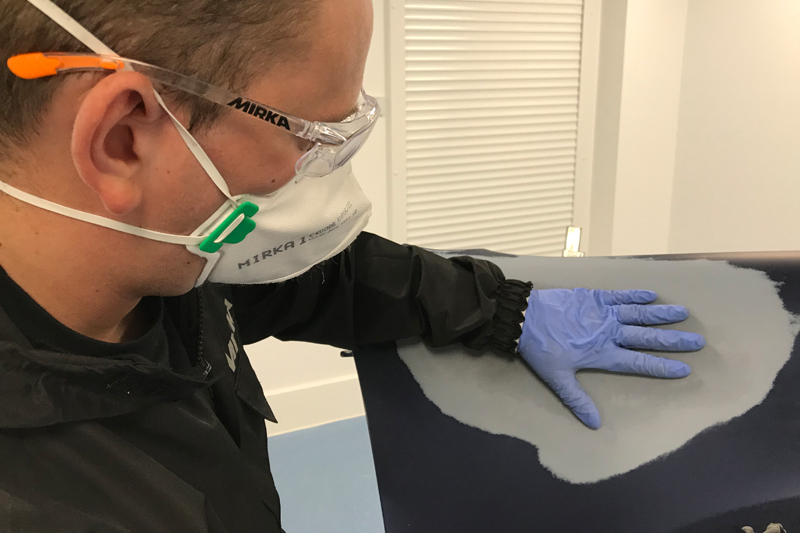

Action: Apply dry guide coat.

Use: Either Mirka black or white powder guide coat, depending on filler colour.

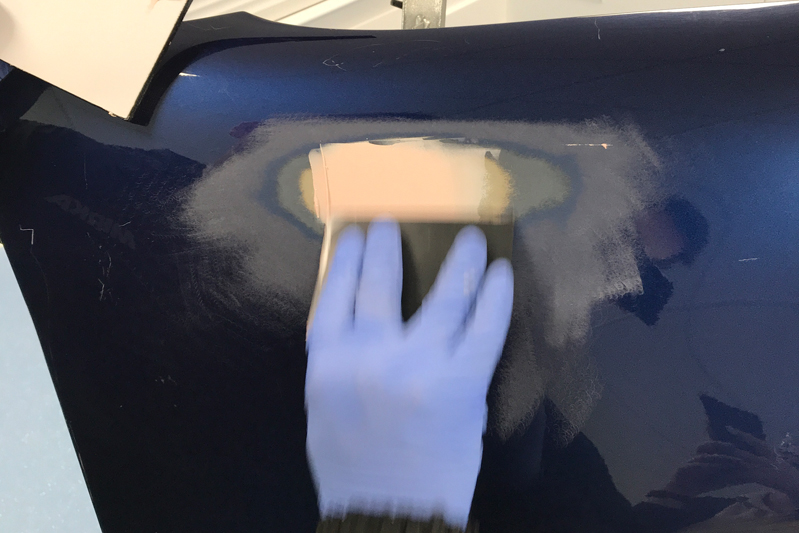

STEP FIVE:

Action: Block sand filler area.

Use: Abranet P80 or P120 or P180 strip, dependent on repair size.

STEP SIX:

Action: If required, apply additional filler to imperfections in repair.

STEP SEVEN:

Action: Re-apply Mirka dry guide coat and block sand.

Use: Abranet P120 or P180 strip.

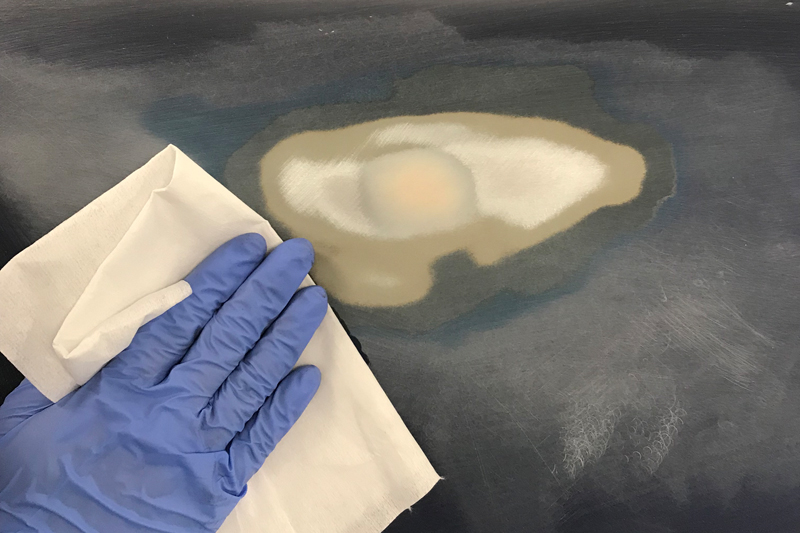

STEP EIGHT:

Action: Clean and inspect repair, and move to the second stage.

Second stage

STEP ONE:

Action: Sand the repair area. Feather out the paint edges from panel repair even further.

Use: P320 disc and Gold Flex Soft P320

STEP TWO:

Action: Prepare around the repaired area for primer. De-grease and inspect the repair area.

Use: P500 disc

STEP THREE:

Action:Apply dry guide coat to primed area.

Use: Use either Mirka black or white powder guide coat, depending on the colour of the primer.

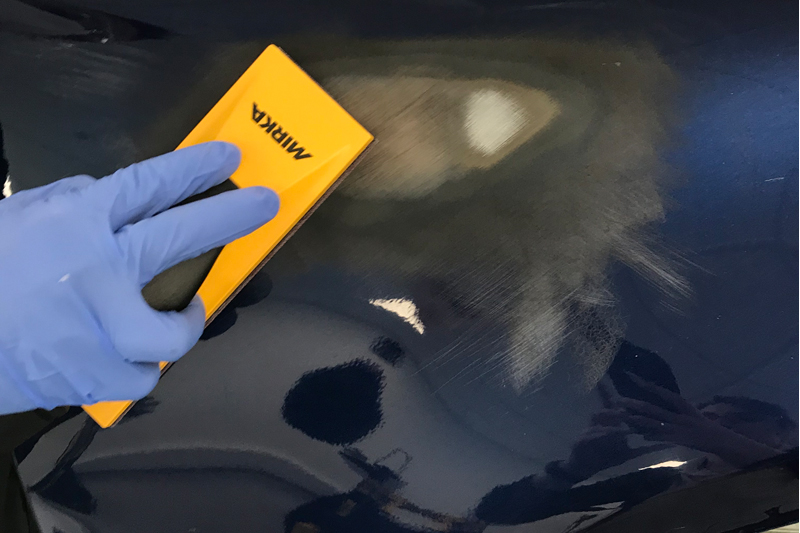

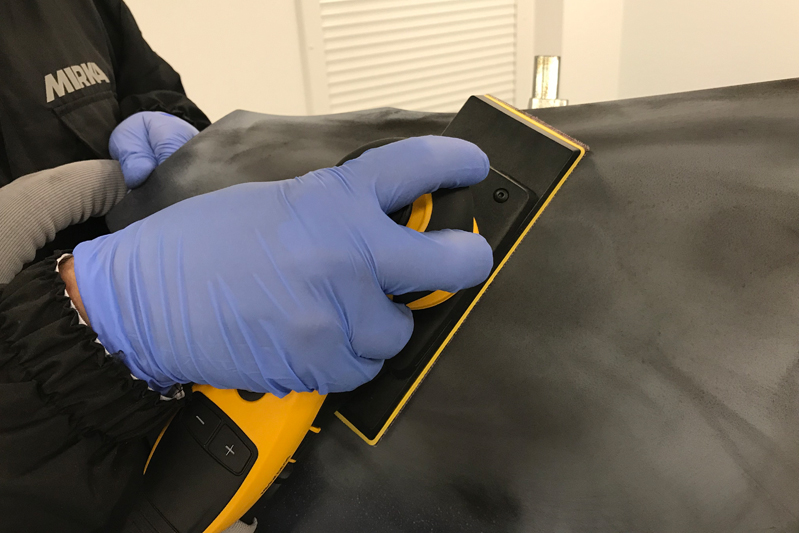

STEP FOUR:

Action: Block the sand primed area to the shape and curvature of the panel.

Use: Abranet P240 or P320 strip.

STEP FIVE:

Action: Sand awkward areas.

Use: Mirka Gold Flex Soft P500-P800.

STEP SIX:

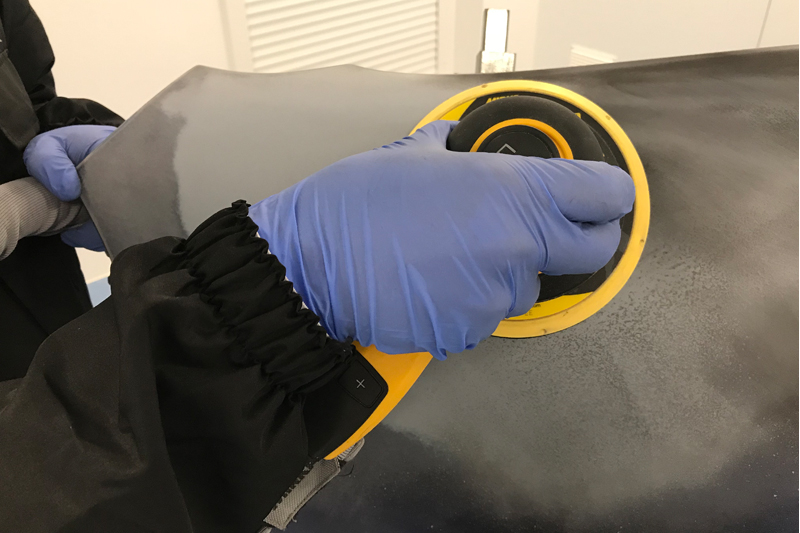

Action: Re-apply Mirka dry guide coat and machine sand primer.

Use: P400 or P500 disc with interface pad.

STEP SEVEN:

Action: Blend the panels either by hand or with a machine.

Use: Mirlon Grey UF with water for hand sanding. For machine sanding, use P800- P1000 Gold, Abralon or Polarstar.

STEP EIGHT:

Action: De-grease, inspect the repair and move to paint.