The Eclipse Jaltest package is a multi-brand diagnostics solution for many of the commercial vehicle fleet operators in the UK. Here, the company describes how to undertake a transmission calibration on Volvo articulated trucks of D and E series.

The Volvo articulated trucks of D and E series all use the Volvo ‘Powertronic’ automatic transmission system. This needs to be occasionally recalibrated for number of reasons, which can include either component wear, or replacement of damaged components. Recalibration is then necessary to ensure that the smooth gear shift is re-established, in order to maintain the ride comfort and performance that is expected.

This calibration process requires advanced diagnostics from a tool such as Jaltest to be able to adjust and tune the transmission to deliver the usual performance. Given the recalibration alternatives identified above, the following two case studies show the procedure following component replacement or adjustment to compensate for wear.

First Case: After carrying out a repair or replacement of transmission components, the following process is carried out:

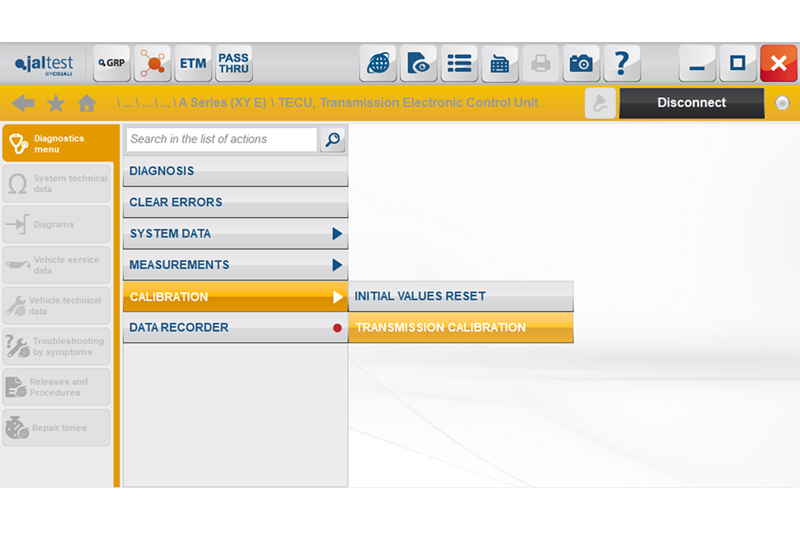

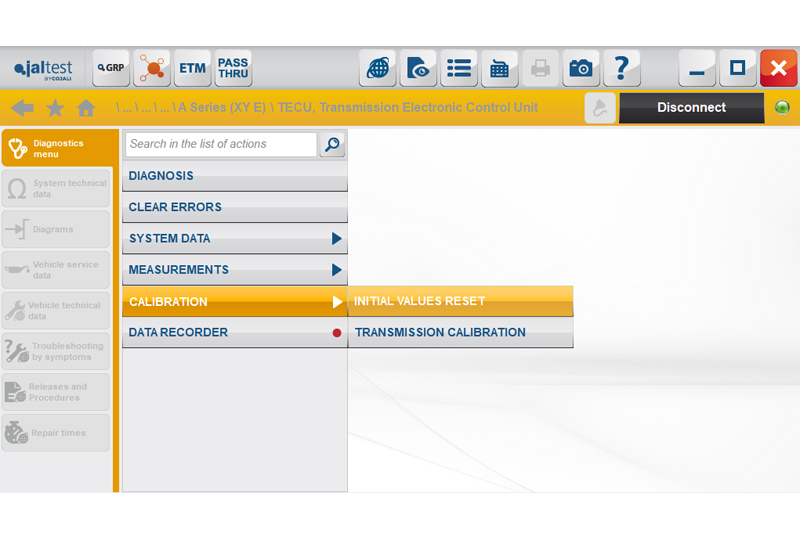

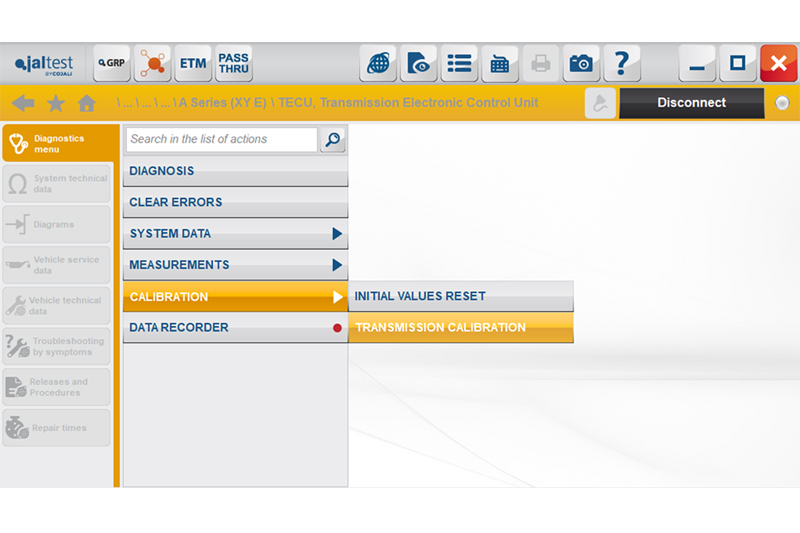

1- Carrying out the initial values reset.

With this element of the process, the values stored in the control unit will be deleted prior to beginning the calibration of the vehicle transmission.

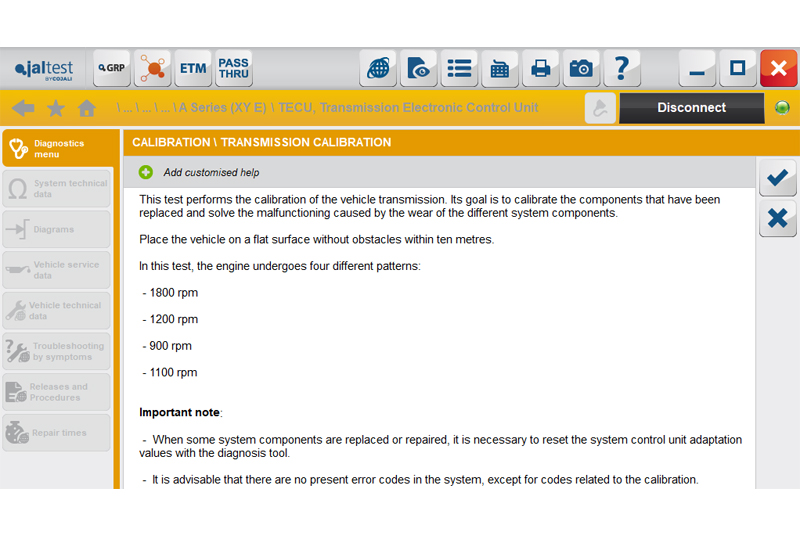

2- Carrying out the calibration process.

The second phase of the process continues the calibration by utilising Jaltest to set the filling times and pressure parameters of the transmission clutches in the control unit (Figures 2 & 3), using these values for the ongoing vehicle operation. Using Jaltest to carry out necessary adjustment of the transmission system can solve operational issues or vibrations of the transmission caused by the component wear.

To carry out this process when no transmission component has been replaced, it is only necessary for the calibration process to be carried out. This process needs to only modify the filling times and pressures of the transmission clutches in the control unit, rather than the more involved process that was required when a component was replaced.

The transmission system of the Volvo units is one of their most fundamental and complex features, and carrying out timely repairs and maintenance will massively increase the lifetime of the vehicles whilst also reducing overall operational running costs, including those of future maintenance.

In fact, carrying out this calibration is one of the most important elements of an official service. Ignoring the process or wrongly calibrating the system could create a repair cost that would easily exceed the cost of the Eclipse Jaltest diagnostic product.

This high-end functionality across a multitude of brands has resulted in the Eclipse Jaltest product being utilised by a large number of main dealers who previously were limited by the OE manufacturer’s tools, but now have the opportunity to extend the service and repair facilities to include more vehicles and customer fleets.

These dealers, along with all other Eclipse users, also benefit by the business being developed around the core philosophy of Vehicle Related Customer Support. This service is available from when the system is first purchased, and throughout its life.