During the colder months, it is essential that technicians are aware of the full effects of the dropping temperatures. ZF explains why it’s essential to undertake axle checks in the workshop.

“With a prolonged season of freeze-thaw conditions potentially in store, standing water can pose a real problem for axles, especially without proper preventive maintenance,” explains Wayne McCluskey, Technical Training Manager at ZF Aftermarket.

Breather system checks

ZF mechanical axles are sealed against water splash, but they aren’t designed to have fording ability. Negotiating flooded roads or shallow fords can cause water to enter the axle, most commonly via the axle’s breather system, which is usually a flexible pipe that runs from the axle housing to a dry area of the chassis.

The breather system may be overlooked during routine vehicle servicing – some technicians even admit to being uncertain about its function. Wayne suggests that checking that it is in undamaged condition, is clear of blockages and is correctly routed to a dry area should be considered as an important part of the maintenance schedule. He also recommends that the following items are regularly inspected:

- Check that the breather hose is present, undamaged and free of blockages. ZF typically specifies tubing of 6 to 8mm diameter, routed to avoid chafing and ending in a hollow space protected from dirt and spray water.

- Ensure that breather hose connections, such as the elbow adaptor where the hose joins the axle case, are intact and secure (Fig 1).

- Check that the end of the breather hose is higher than the connection to the axle, and the hole where it enters the body cavity is sealed with silicone sealant (Fig 2).

Inspect axle seals

Investigate any lubricant seepage from the hub and pinion seals, which would indicate that they are damaged or worn. The seals are vulnerable to water entry, not only when traversing floods or fords, but also during cleaning; these areas are not designed to withstand persistent, intensive water impact. Steam cleaning or pressure jetting in the vicinity of the breather pipe or sealing areas should be avoided on all axles for this reason.

Towing precautions

Apart from exposure to standing water, it’s important to be aware of other less obvious water entry possibilities. If the vehicle needs to be towed, it’s common practice to disconnect one or preferably both of the half shafts, or the propshaft, to prevent transmission damage. If this is the case, always ensure that exposed output flange shafts are covered to protect them.

Diagnosing water ingress

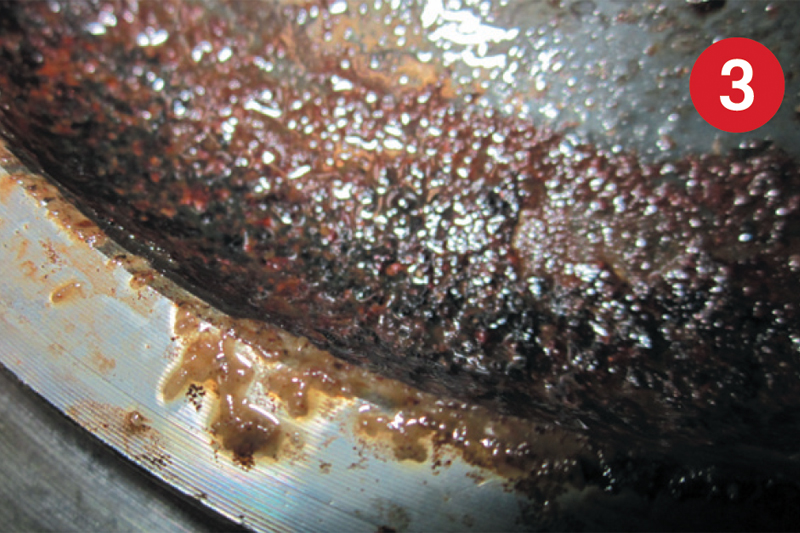

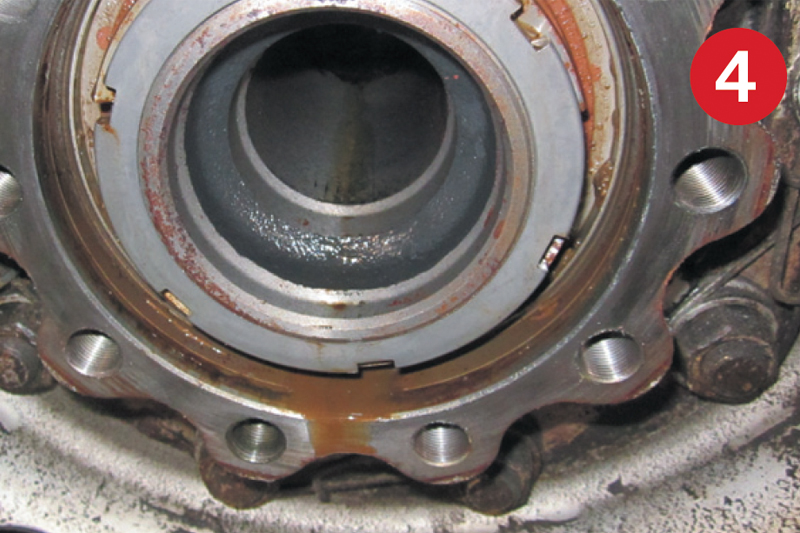

Water ingress is often only discovered during oil changes, although in some cases, the onset of rust may be evident at one of the half shaft flanges (Fig 3) or at the wheel bearing (Fig 4). Where this occurs, it will quickly compromise the ability of the lubricants within the axle to provide corrosion protection and wear prevention. The axle will begin to corrode inside the axle case (Fig 5), with the resulting contamination causing pitting of the bearings and/or scuffing to the crown wheel and pinion or the differential, accelerating wear.

The first indication of such damage is usually noise, although axles have been known to lose drive or suffer bearing collapse without any prior warning signals. This indicates that the axle internals have suffered severe damage, with the inevitable result being a hefty repair bill. If water is suspected to have entered the axle, this should be brought to the immediate attention of the vehicle operator, with a recommendation that the oil be changed, or at least sampled in the first instance to check for contamination.

Oil sampling and lubricant replacement

Oil sampling is an excellent way of monitoring axle condition to gauge potential lifespan, and can also provide early warning of the presence of water. While many operators regularly oil sample engines and gearboxes as part of their maintenance regime, the axle is often overlooked. If irregularities in the axle oil are detected, an oil change must be carried out. In this situation, it is essential to also check the grease filling in the hub carrier, in the inner rings of the compact wheel bearing and in the flange shaft. When replacing lubricants, precautions should be taken to avoid introducing water during the operation. Drums of lubricant kept outside should be stored in a roofed area to prevent pollution with rainwater, and filling and transfer equipment should be checked for water contamination before use.

Lubricant specifications

A ZF axle should always be serviced and maintained in accordance with both ZF’s and the individual vehicle manufacturer’s guidelines. Adhering to the correct oil specification and observing the replacement intervals is crucial for long and trouble-free axle life. Mineral oils typically need to be changed at 60,000 miles or yearly intervals – whichever occurs sooner – and hub greases generally need renewing every 500,000 miles or four years.