BPW outlines its air suspension offering for 9 tonne axles and provides some best practice advice for servicing and maintenance.

Air suspension maintenance very often receives cursory attention within the statutory periodic inspection cycle. However, it is an important sub-assembly and is responsible for connecting the trailer chassis to, and distributing the load onto, the axle.

It must also be remembered that in an air suspension system, the axle beam is an important component of the suspension system. The connection between the axle beam and the trailing arm is key to the performance of the suspension.

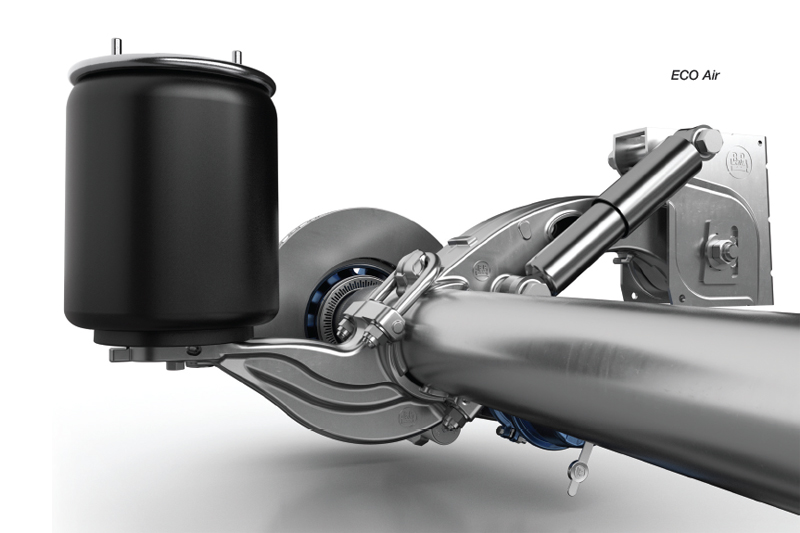

Both suspensions provided by BPW, Airlight ll Round and ECO Air, provide the same physical properties, allowing the company to offer solutions to cater for different types of trailer design and operating conditions. In order to understand the maintenance requirements of an air suspension system, it is worth spending a little time understanding the principles of the operations.

The suspension system on a vehicle comprises the tyres, air bags, trailing arms and bushes. It allows relative motion between the trailer chassis and the road whilst still giving support. The suspension system contributes to the vehicle’s roadholding and braking performance to ensure that the trailer’s payload is given the best possible ride quality.

ECO Air

The design of a suspension system is generally a compromise, and this is more so with a trailer where the difference in ground weight varies so much between unladen and fully laden. It is really important to ensure that the tyre is kept in contact with the road at all times, as this is all that gives the vehicle its braking adhesion and lateral stability.

In terms of maintenance, the regime is quite straightforward and involves periodic inspection for wear and damage and checking the security of the fastenings. The air bags contribute very little to roll stability (around 7%). Stability is mainly provided by the axle beam and the two trailing arms which combine to form a large ‘U’ shaped anti-roll bar.

It is essential, therefore, to ensure that the ‘U’ bolts are kept tight. Different types of suspension have different sizes of ‘U’ bolts and different requirements for torque settings and methods of checking. BPW’s service manuals give the procedures for the different suspension systems that it produces. The presence of corrosion around the interface between the spring saddles and axle beams is a tell-tale sign that the assembly is loose, and attention is required to prevent further secondary damage to the axle beam from movement between it and the spring saddle.

Torque settings

The U-bolts on the BPW suspension ranges are designed to stretch when tightened to the correct torque and therefore must be replaced along with the nuts and washers if the assembly is dismantled. It is essential to use the correct tightening method settings on U-bolts.

Air bags

Air bags need to be inspected for damage, leaks and perishing: this is best done during the statutory periodic inspections. The air bags are made of rubber which naturally starts to age immediately after the manufacturing process is completed. In more recent years legislation has dictated that ageing additives must comply with the new directives and this has shortened the life of air bags.

Perishing manifests on the roll of the air bag where the rubber rolls under adjacent to the piston, and particular care should be given to inspections in this area. Look at the piston for signs of damage from stones or contact with kerbs or loading bay reversing guides. If the ride height of the suspension is incorrect, or if the trailer has too much slope, then this will cause the air bags to either stretch out or ride on the internal bump stops. Either of these situations will cause damage.

Trailing arms

Trailing arms need very little attention, save to check for damage. Where single leaf trailing arms are used, BPW always fits a catch plate: this is a strip made from galvanised steel that encompasses the trailing arm and is trapped under the spring plates in the area of the U-bolts. If a trailing arm breaks, the catch plate will hold the axle in place until the vehicle can receive attention in the workshop. This will prevent the tyres and air bags from damage due to the axle becoming grossly misaligned.

The catch plate should always be replaced in order to maintain this safety feature. Any detritus that has built up between the catch plate and the trailing arm should be removed periodically. Dirt buildup in this area will encourage damp which will eventually corrode the top of the trailing arm leaving it vulnerable to breaking. The rubber bush in the eye at the front of the trailing arm gives little trouble. It can be checked by attempting to move the trailer with the brakes on: there should be no more than 2 or 3 mm of movement between the trailing arm and the hanger bracket in the Airlight II suspension.

On the ECO Air suspension, a different method of checking for bush wear is used. This is detailed in the BPW workshop manual. In all cases, the trailing arm pivot bolt should be kept at the correct torque. If the bolt is loosened or removed, then it should be tightened with the trailing arm set up at the normal ride height for the suspension. This will ensure that there is no excessive wind-up of the rubber bush.

Shock absorbers

Shock absorbers will need to be checked for leaks and security. Again, this is a task for the periodic inspections. It is the shock absorber’s job to ensure that the tyre is kept in contact with the road surface. The shock absorber on a trailer axle is designed to work with a maximum axle load of 9 tonnes. If the trailer is not fully loaded, then the shock absorber is over-damping the axle.

Sometimes, during manufacture, the shock absorber can be overfilled with oil and this is ejected when the trailer is first used. The oil is ejected as a fine mist and covers the body of the shock absorber. This should be wiped off initially and all should be well, but if misting re-occurs or oil runs down the body of the shock absorber, then it could be faulty and may need to be changed. It is important to keep the shock absorber fixing bolts at the correct torque or it will run loose and the fixings will become damaged.

All air suspensions are designed to run at specific ride heights and if the trailer is used with the suspension set up at a different height, then damage can occur to air bags, bushes and U-bolts. Some axles are cambered and any deviation in ride height will change the angle of the axle to the horizontal. This will translate the camber into toe-in or toe-out and result in accelerated tyre wear.

BPW offers two types of air suspension for 9 tonne axles – the conventional sprung steel trailing arm of the Airlight II Round and the cast trailing arm of the ECO Air.