Turbocharger failures are often blamed for various faults in the engine. BTN Turbo argues that this is almost exclusively not the case. Here are some pointers for finding the real cause.

Low power, excessive noise or smoke are often blamed on the turbo. Yet turbochargers are extremely reliable – only 1% of so-called turbo failures are due to a fault with the turbo itself.

The turbocharger is an integral part of the engine’s air, fuel, cooling and oil systems, so any problem in these systems will have an effect on the turbo. Even if a diagnostic fault code points to the turbo, it may simply be highlighting the result, not the cause. Before you fit a replacement, it’s essential to find out what caused the turbo to fail – or you may just repeat the problem.

Check hoses

A blocked filter or intercooler, obstructions, leaks or splits in any hoses or pipes, or even using non-OE spec parts, can lead to turbo failure. For example, a split air intake hose can make the turbo over-rev and over-boost.

Check specification

Is the engine modified or worn out with low compression? If the turbo isn’t receiving the amount of energy it was designed for, it won’t perform properly or may fail prematurely. Even simply overfilling the engine oil can over-pressurise the system and damage the turbo – or suggest there’s a turbo problem.

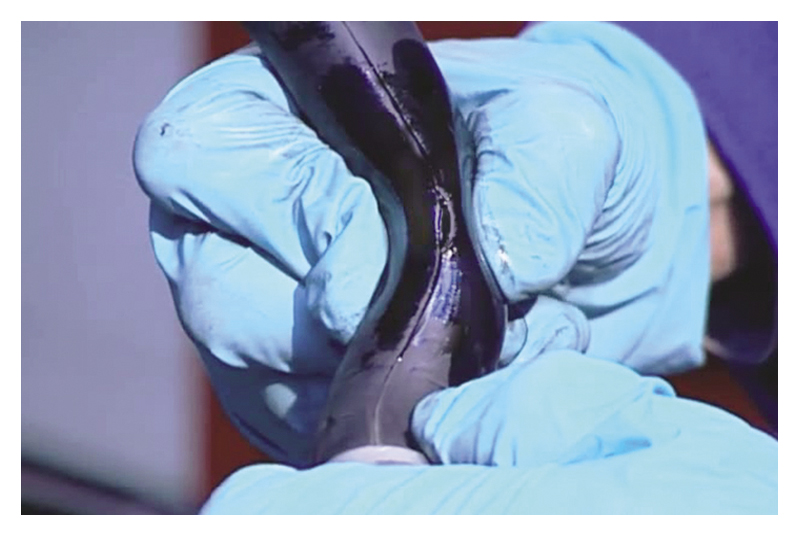

Check the oil

Over 90% of turbo failures are oil related: either oil starvation or contamination, so examine this area first when you’re searching for a fault. Remember, it’s vital to change the oil and replace the oil and air filters when you fit the new turbo.

When a turbo stops working, it seems obvious that it should take the blame. However, in nearly every instance, the reason for the failure almost certainly lies elsewhere.