Applying to all car-derived vans and larger LCVs, Schaeffler is urging technicians to follow its 4T guidelines during the service and installation of its INA belt systems and components.

4T was created by Schaeffler’s team of REPXPERTs in a bid to boost service and installation best practice, helping to avoid fitting errors that can lead to premature belt failure:

■ Temperature: do not start work until the engine has completely cooled down

■ Tools: the correct tools must be used in accordance with vehicle manufacturer (VM) instructions

■ Torque: use a torque wrench to tighten all bolts to the correct VM specifications

■ Tension: the belt tension must be accurate, correct and to VM recommendations

INA Belt System Specialist, Tim Adams, said, “We are not trying to teach mechanics how to do the obvious, but it is amazing how many problems can be created by not following these simple rules in the workshop. 4T is easy to remember, and adhering to its principles will help to prevent fitting errors, saving time, effort and money for both the garage and its customers.”

Investigate and repair

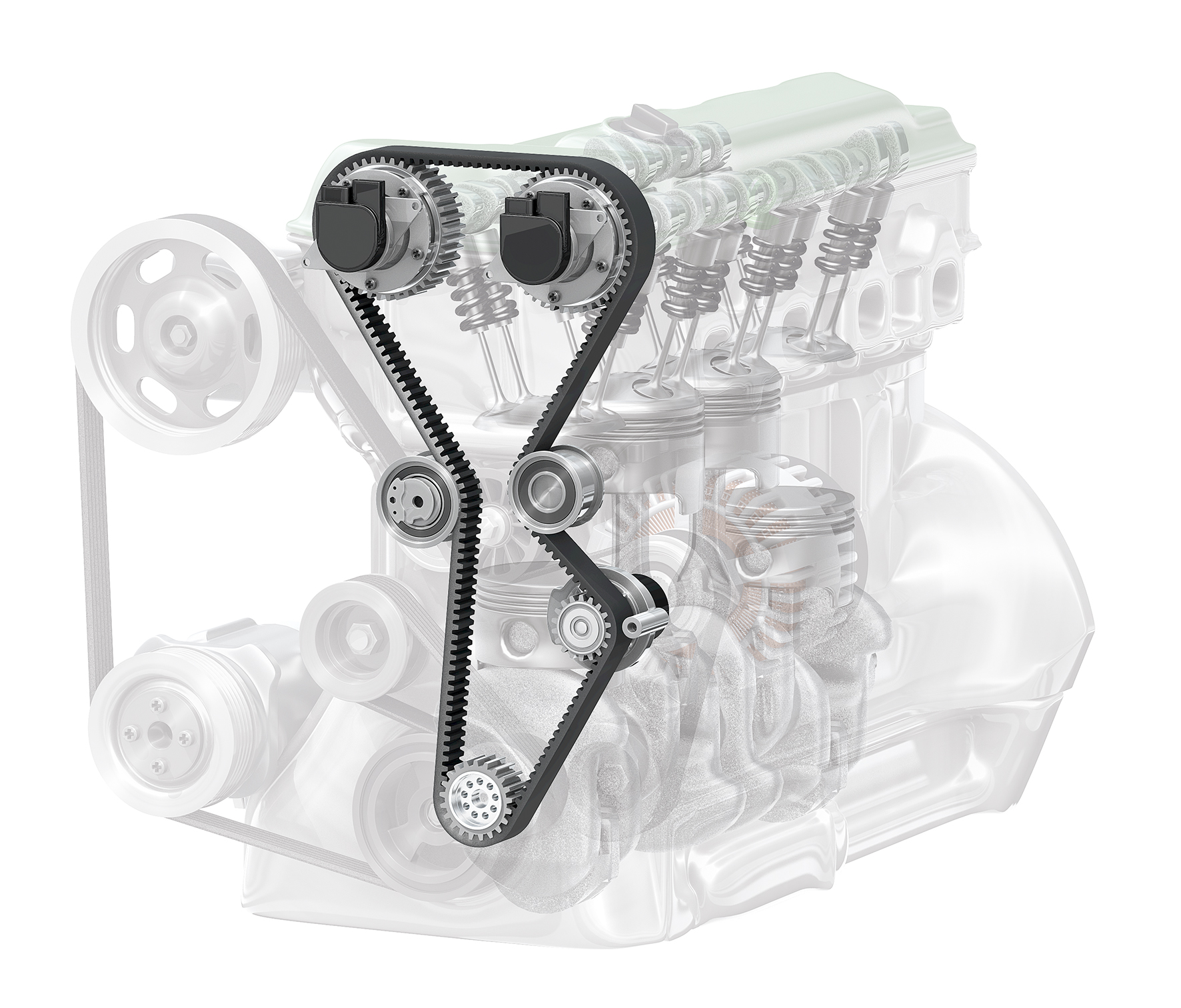

If drivers notice unexplained noises or vibrations when driving, the cause should be investigated by a technician immediately. If a timing belt system replacement is required, Schaeffler and VMs recommend that all components need to be changed at the same time to reduce the risk of major engine damage.

The company believes that by using the INA range of Timing Belt KITs and KIT+, technicians will save time by having everything they need for a professional repair in just one box, with the KIT+ range including the water pump for belt driven applications.

Belt and tensioner diagnosis A broken timing belt and/or tensioner can cause engine failure,

which is why it is imperative that technicians check the system for wear during a routine service, and always replace it at the VM’s recommended change point.

Diagnosing what causes a timing belt to break is not straight forward, but common reasons for failure can usually be classified as follows:

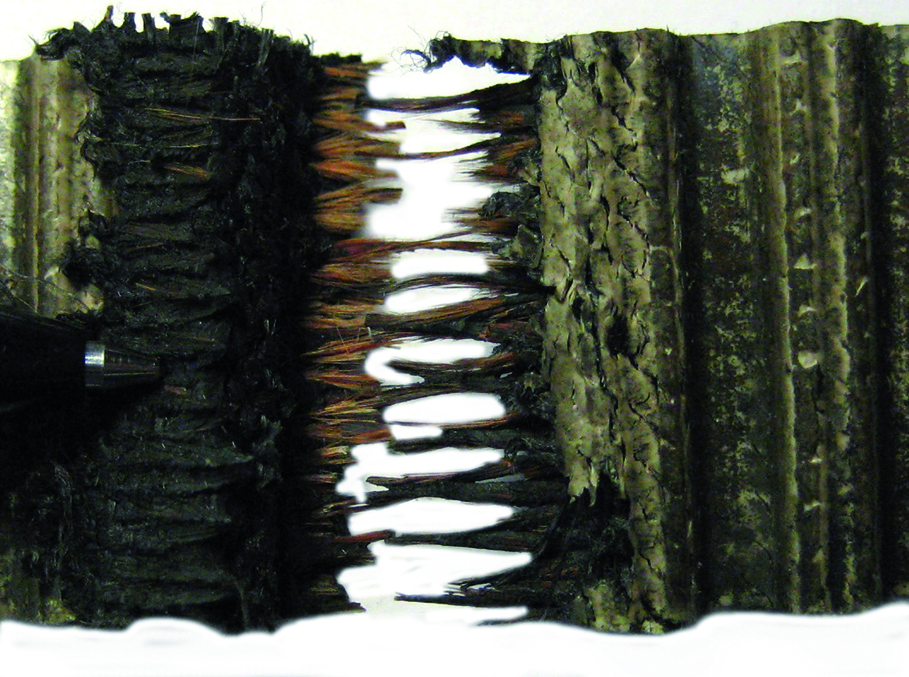

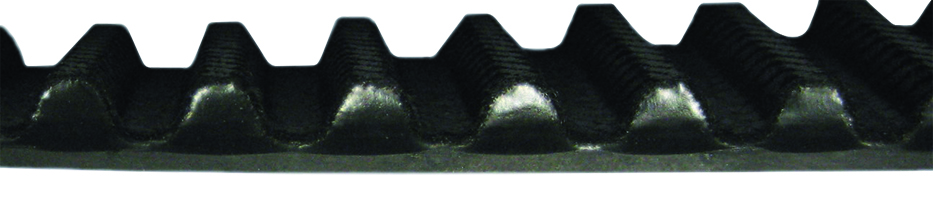

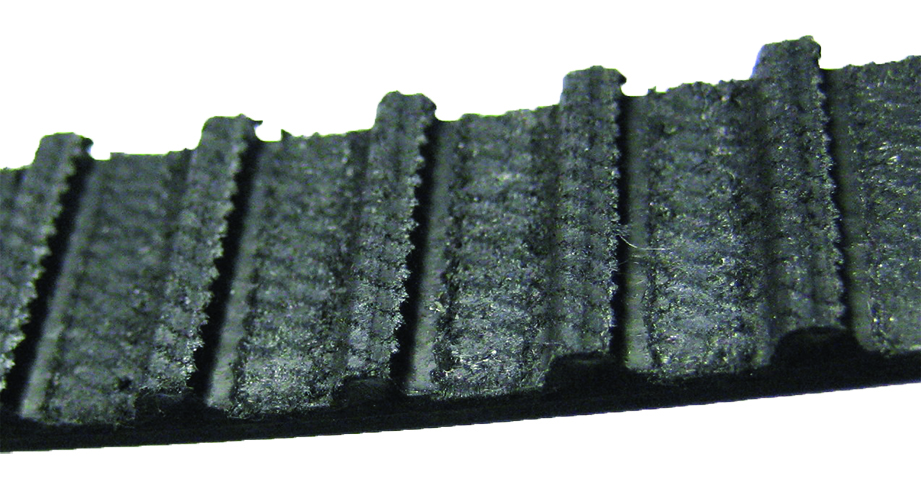

■ Straight break – caused by the belt ‘crimping’ (usually a fitting or handling error)

■ Jagged break – caused by incorrect/excessive tension (fitting error) or a foreign body entering the drive system

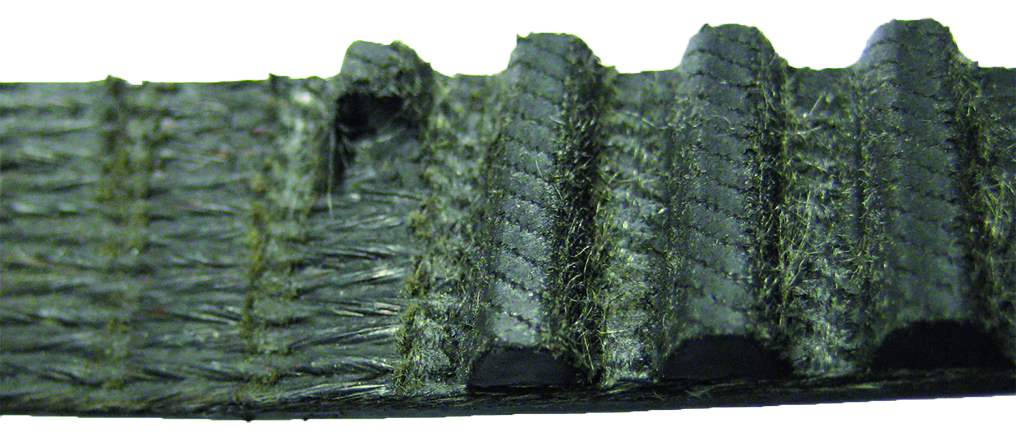

■ Sheared teeth – caused by incorrect tension and misalignment (fitting error), or the recommended change point has been exceeded

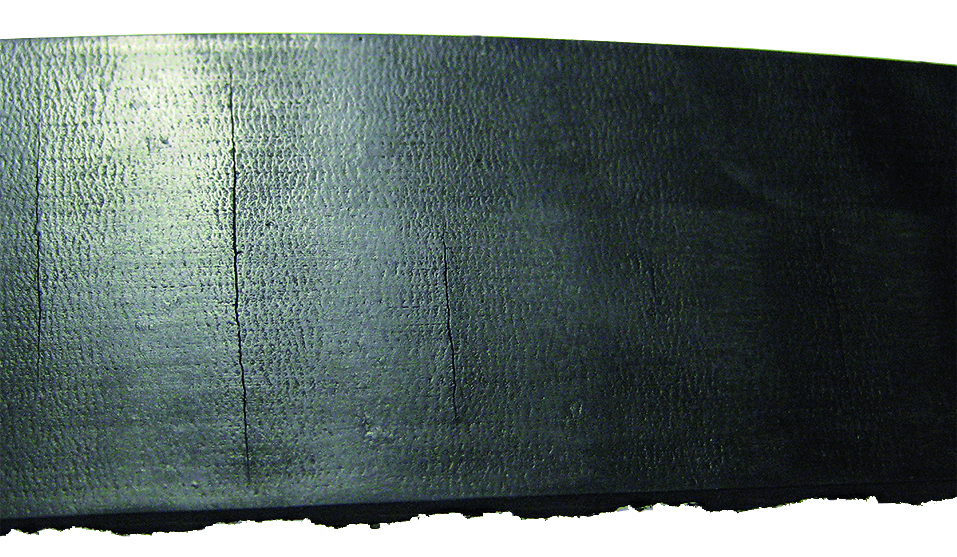

■ Cracked back – caused by heat exposure and/or change point exceeded

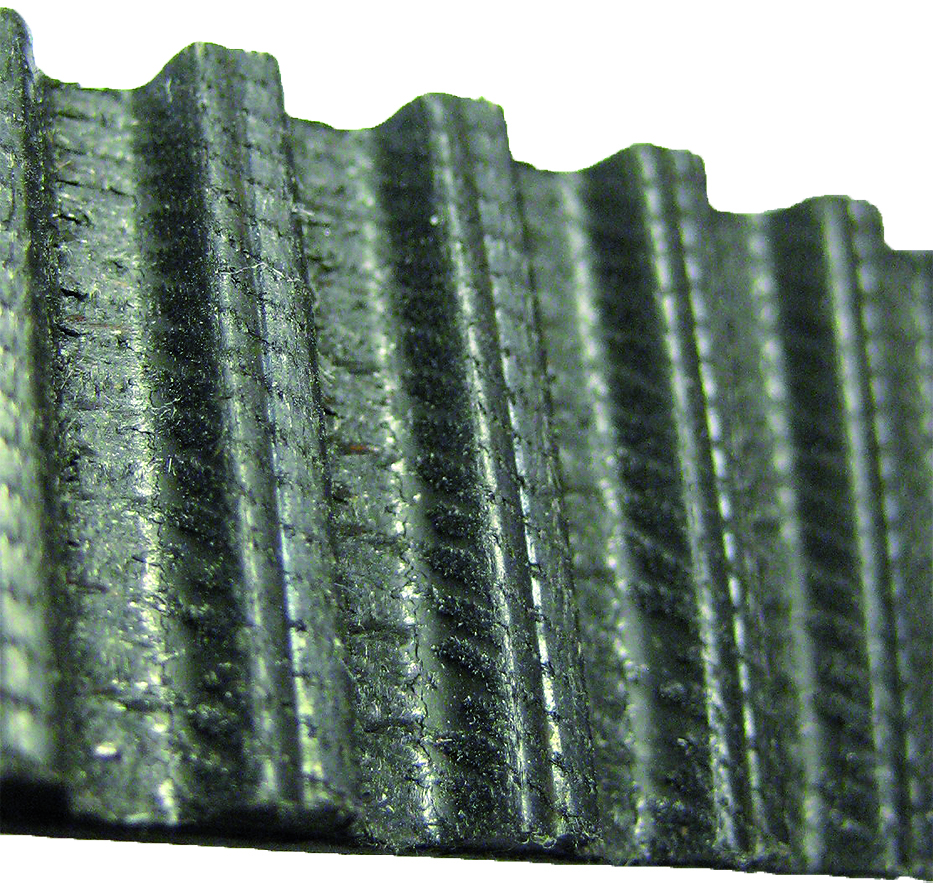

■ Side wear/polishing – caused by misalignment (fitting error)

■ Worn teeth flanks – caused by incorrect/excessive tension and misalignment (fitting error), and/or exceeding the change point

■ Worn teeth flanks – caused by incorrect/excessive tension and misalignment (fitting error), and/or exceeding the change point

Signs of a broken tensioner include the following:

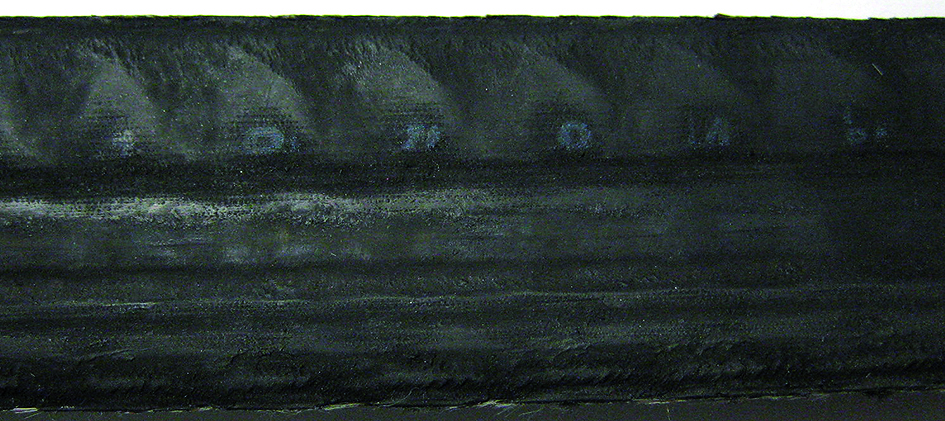

■ Marked belt back – caused by incorrect tension and alignment (fitting error) or a foreign body entering the drive system

■ Gap (land) wear – caused by incorrect/excessive tension (fitting error)

■ Contaminated belt (grease/oil) – caused by other defective components, damage or an incorrectly installed timing belt cover

■ Worn end stop/broken stop pin –caused by an incorrect tension (fitting error)

■ Contact damage on pulley rims – caused by misalignment (fitting error) and defective components, such as water pump bearing

As well as creating a useful poster that contains all the above information, Schaeffler also provides the REPXPERT portal as a useful tool for technicians that wish to gain instant access to VM fitting data, technical guides, product information and training dates.