CVW hears from Volker Brinkmann, Head of Communications at the Diesel Technic Group, on how imprecise clutch fitment can lead to the accelerated wear of this crucial component.

The dreaded rise of revs and lack of acceleration signals the fateful onset of a slipping clutch. These symptoms are often accompanied by difficulty when selecting gears or complete failure. A clutch is just like any other wear item; one day it will need replacing. The difference is that it can be tricky to predict failure. Some clutches can last tens of thousands of miles more than others, but why?

“A clutch’s service life is dependent on a number of factors, from fitment and component quality, to a vehicle’s overall condition, the way the vehicle has been used and even the way it’s been driven,” explained Volker Brinkmann, Head of Communications at the Diesel Technic Group. “Intense heat is generated during clutch operation, exacerbated by factors such as excess pressure, centrifugal forces and friction. This heat can accelerate clutch wear and reduce its ability to operate efficiently. A vehicle’s exposure to excess heat will have a direct impact on how long we can expect it to survive while still enabling the changing of gears, transferring of torque, absorption of vibration and protecting the drive assembly. Of course, no two vehicles are the same. They’re subjected to different conditions, payloads and drivers.”

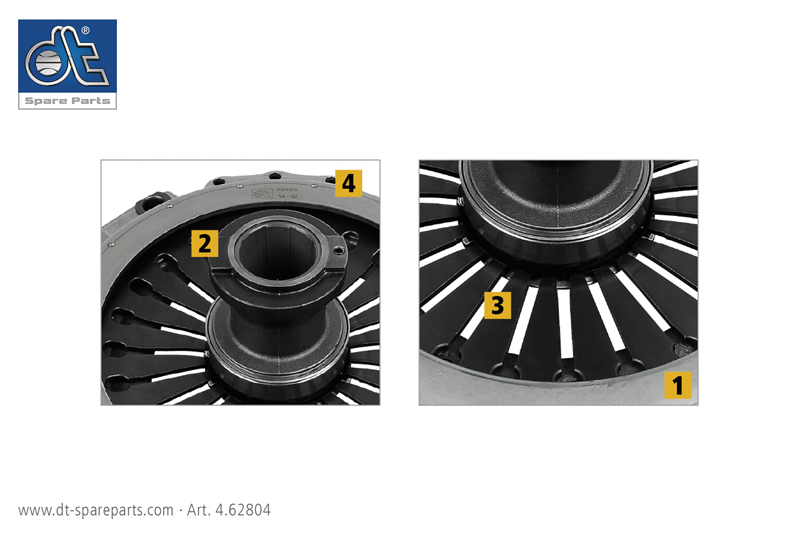

Volker explained that while component quality plays a huge part in determining clutch life, especially for replacement items, it is only one aspect. Correct and precise fitment is just as important. For example, optimal alignment of clutch, flywheel and engine crankshaft through use of a mounting mandrel is absolutely crucial.

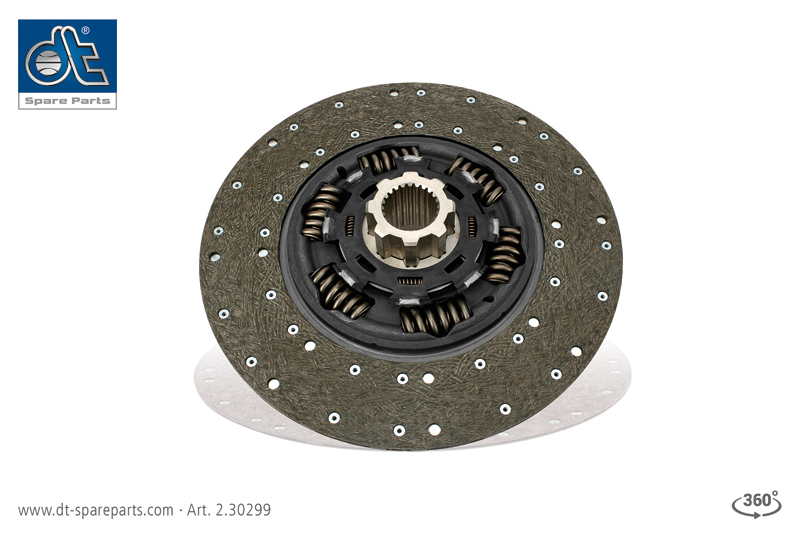

Volker continued, “Hub profiles should always be lubricated to prevent the clutch from slipping. Of course, service teams should ensure that component replacement meets vehicle manufacturer standards and that wear values are reset in order to fully understand the extent of future clutch wear.” In terms of component quality, DT Spare Parts, the aftermarket arm of OE supplier Diesel Technic, manufactures its clutch plates with friction lining, which ensures a balance of performance and service life. Torsion springs are fitted within the company’s plates to reduce the speed and torque fluctuations of the engine, helping to reduce transmission noise and wear.

Correct fitment not only ensures reliable operation, but minimises vehicle downtime, and reduces the risk of premature wear and further unscheduled maintenance; a broken vehicle is costing, not earning, money.

You’re only as strong as your weakest link

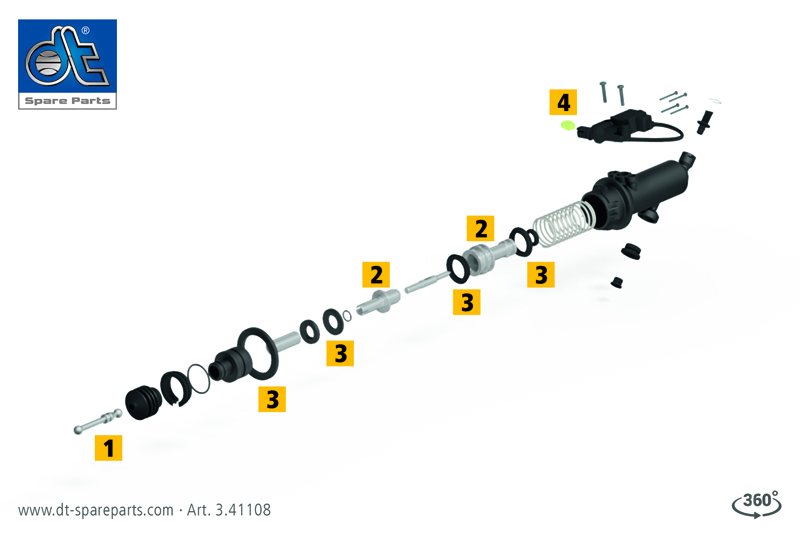

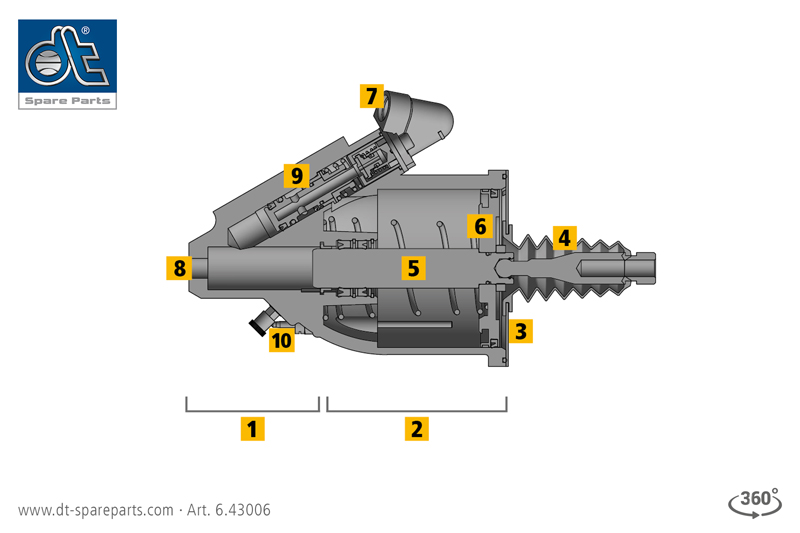

There’s more to a clutch than the physical assembly linking gearbox and engine, and, according to Volker, the clutch servo is an often-overlooked component. The servo is made up of almost 80 intricate parts and enables a driver to operate the clutch with reduced effort. It enables a delicate, accurate use of the pedal through pneumaticallyassisted hydraulic actuation, instead of relying on the driver having a bodybuilder’s left leg.

“Component quality and fit is just as important when considering servo replacement,” he explained. “Taking DT Spare Parts’ range as an example, we ensure that every clutch servo has an aluminium housing and is tested for density and porosity, ensuring maximum durability, increased service life and avoiding traditional servo weak points. Our components are manufactured using finely ground hardcore chrome-plated piston rods, and are put through a rigorous testing programme to ensure consistency of operation and part quality. This is complemented by the fitment of mounting holes with precision fit bushings, which ensure optimised alignment during assembly.”

Modern clutch servos don’t just make using the clutch easier, they can also help prolong the assembly’s life expectancy. “Traditionally, servos are hydraulic slave cylinders, and a pneumatic cylinder reduces the actuating force on a clutch pedal, but modern systems can incorporate a travel sensor, too,” continued Volker. “This sensor relays the positioning control values connected at the pushrod to the control unit, preventing excessive clutch wear caused by riding the pedal and ensuring a prolonged component life.”

2. Hydraulic cylinder

3. Cover

4. Boot

5. Piston rod

6. Servo piston

7. Compressed air connection

8. Hydraulic connection

9. Control valve

10. Wear indicator

On-screen direction

As part of its support network, Diesel Technic offers how-to installation videos using its mechanics to guide users through fault-finding and component fitment. The videos are applicable to the complete range of 140 clutch kits – all with a 24-month guarantee – available to the commercial vehicle aftermarket and can be viewed at the DT Spare Parts website.