Henkel gives advice on how to correctly apply its Teroson MS 9320 SF seam sealant to keep vehicles looking brand new.

In order to keep a fleet looking top standard, it is crucial to reproduce the same quality and visual appearance that is provided by the original OEM seams, which will also help to avoid corrosion caused by environmental factors.

Henkel claims that its sealing technologies allow commercial vehicle workshops to reproduce all kinds of OEM textured beads with just one seam sealant product, Teroson MS 9320 SF. The company says that its product can produce ribbed beads as well as traditional textured beads, and standard seams are also possible with its isocyanate and solvent-free modified silane polymer.

Teroson MS 9320 SF can be used for both sprayed and brushable applications, and it exhibits very good adhesion to a wide range of substrates without the use of a primer. The fast-curing sealant may be overpainted, and it has excellent UV resistance and weathering performance.

With the following instructions, workshops can recreate those traditional, textured seams with spray seam sealing/spray surface coating.

Tools

- Chemical resistance gloves

- Masking tape

- Safety glasses

- Spray nozzles

- Application gun

1- Preparing the cartridge

Remove the bottom cover and open the cartridge. Screw the dispensing nozzle required (inner nozzle) onto the cartridge.

2- Attaching the air cap

Insert the cartridge into the spray gun and screw on the blue screw collar. Screw with air cap fully into the blue screw.

3- Using the air gun

Adjust the compressed air gun and the screws – the supply pressure must be 6 bar and 10 bar. Start the closed sealant flow and open the air flow completely. Position the gun towards the substrate and press the trigger. Slowly open the sealant flow to get a base structure (different ratios of sealant and air supply will produce the required texture).

4a- Spray seam sealing

Hold the nozzle in the vertical position and move it at a right angle to the seam approximately 4cm above the surface. In case of overspray, adjust the distance. Let the product cure.

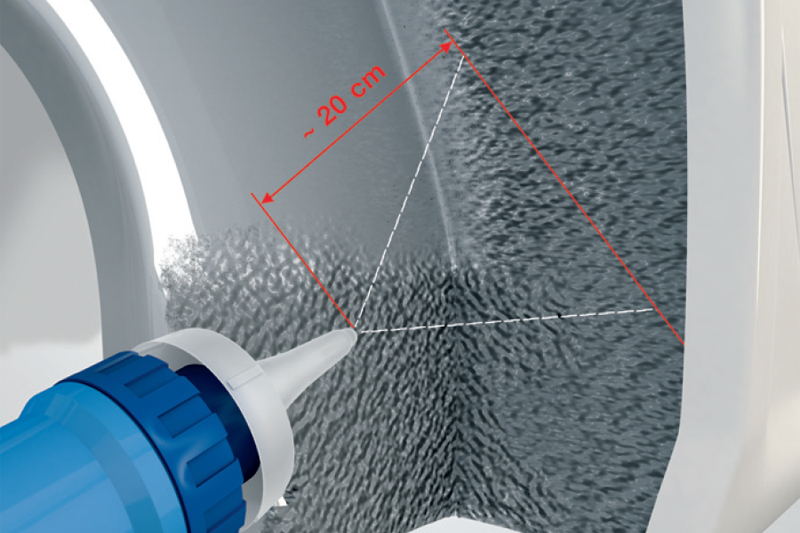

4b- Spray surface coating

For coating larger areas, adjust the distance of the nozzle to the surface to approximately 20cm. Let the product cure.