The optimum disc and pad pairing delivers the best braking performance and life. Knorr-Bremse’s Tim Ford explains the benefits of testing pads beyond ECE R90 requirements.

Ensuring discs are paired with the appropriate friction material is critical for the braking system’s performance. That’s why Knorr-Bremse recommends operators match the disc brake with a compatible pad, both to maximise safety performance and extend the life of the braking components.

The optimum disc and pad pairing enhances braking performance by reducing stopping distances – in tests Knorr-Bremse discs and pads achieved a far shorter stopping distance from 40 to 0km/h compared to competitor products over a range of brake temperatures. It also results in less wear, delivering lower life-cycle costs and vehicle downtime, and the higher thermal resistance means there is reduced transfer of heat from disc to wheel hub.

Pad testing

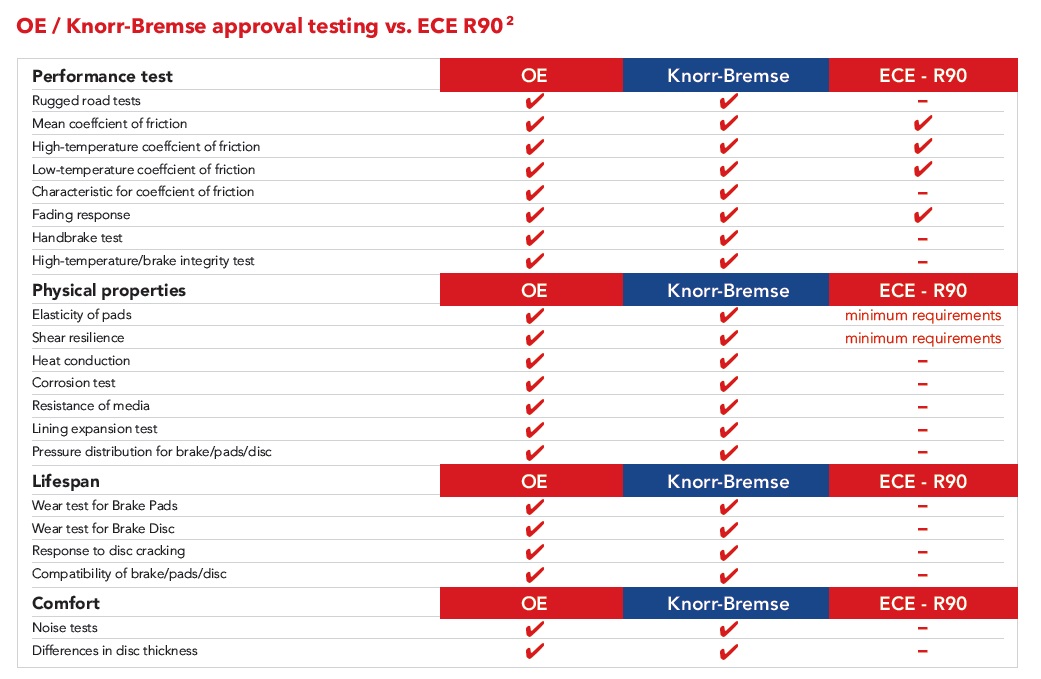

All Knorr-Bremse replacement discs and pads undergo stringent performance tests, far beyond those required to meet ECE R90 requirements. The demands which we and our OE customers require of our brake pads go far beyond those of ECE R90 to offer the market the utmost degree of safety, reliability and comfort.

Brake pads certified in compliance with ECE R90 for the aftermarket are required to meet certain minimum requirements in tests involving brake response, coefficient of friction and quality. However, brake performance, wear and stability of the lining are not fully guaranteed on the basis of ECE R90 tests alone.

As a result, when a vehicle manufacturer selects Knorr-Bremse calipers there is sometimes only one friction material selected for OE fit. Only this material is then type approved and can be guaranteed to provide the necessary braking performance, in line with the type approval.

Knorr-Bremse brake pads for certain applications may feature some or all of these enhancements; partially integral tappets, a tilting edge and brake-in coating. Pads also incorporate a brakein coating to help with new brakes and bedding in.

Pad retention tests

Pads are subject to additional wear and performance tests, including a particularly tough vibration test. We also measure pad-retention over several cycles to check durability of the pad retainer or spring. Should the retainer break in service, it can cause the pads to be lost altogether, resulting in immediate failure of the brake.