FP&S says it has been helping its customers to keep trailer assets operational and on the road through the same-day supply of its range of parts, via a national network of branches for over 20 years. This service, combined with proactive, predictive maintenance, is the recipe for trailer fleet longevity.

Quality makes a difference

If you have invested in quality engineered components for your trailer, you will want to protect that investment – and when the time comes, that means fitting genuine spare parts. If not, and you go for an inferior product, you often find just a few thousand kilometres later that it wasn’t worth it.

This could be due to a number of reasons: the material suffers premature wear; defects are cropping up because production methods are inadequate; or maybe it’s simply that they are not a perfectly matched fit. Ultimately, defects always mean compromising on optimum safety and performance, not to mention having vehicles out of service more often and increased operating costs.

It is for these reasons that more discerning fleets generally fit genuine parts, and by doing so, ensure their equipment’s warranty is not compromised. FP&S stocks a line of genuine parts throughout its national network, seeking to provide customers with access to a full range.

Fleet managers at transport and logistics companies have a lot on their mind – service clients that order a freight transport from A to B; scheduling the right trailer for the right job;  locating a trailer close to the pick-up zone; and defining the best route for a possible return freight, for instance. With the use of modern data systems like trailer telematics, this is not a job for the faint-hearted.

locating a trailer close to the pick-up zone; and defining the best route for a possible return freight, for instance. With the use of modern data systems like trailer telematics, this is not a job for the faint-hearted.

Modern management of trailers and other assets is like traffic control at an airport. You must have an eye for detail, while focusing on the most important thing: delivering on time. While modern technology helps a lot

to improve the quality of road transport, it does not mean that it all goes automatically. The use of trailers and trucks for road transport demands a lot of the material. Heavy loads, steep hills or broken roads can harm your trailer more than you might think.

Maintenance

Now, the last thing you want is your trailer to break down because of the severe usage of that asset. The magical word to prevent this from happening is maintenance. Some view maintenance as an annoying, costly affair and will only repair things on their trailer when it’s really necessary.

Others look at maintenance in a more professional way; they treat every trailer as a part of the family fleet.

A trailer needs love and attention and must be taken care of, both by the driver and by the fleet managers. With regularly scheduled maintenance, you can avoid a lot of trouble and if you want to stay ahead of the competition, you make sure that

your company will never be affected by a trailer incident. In fact, you can foresee technical problems with a trailer and make sure that the repairs are done before the trailer is on the road, going from A to nowhere. This powerful tool is called predictive maintenance.

Predictive maintenance

When you merge all trailer data with information about the mileage, its age and the regularly scheduled maintenance, you can predict the future of a trailer. This forecast is to avoid potential malfunctions in the trailer fleet. A new step towards maximising your business potential, predictive maintenance enables you to gain more control over your trailers’ condition and your future costs.

- Repair of body components such as bumpers,wing flaps, cyclist protection bumpers.

- Repair of pneumatic elements such as brake hand valves, air hoses etc.

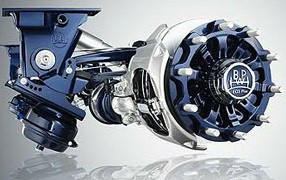

- Repair of rolling gear and suspension: cushion suspension, suspension valve.

- Preparation and pass technical inspection: preventive visit, tailgate control.

- Repair of electric equipment such as lights, lamp, socket, waterproof box.

- Repair of lift-gates: maintenance and installation

- Repair and maintenance of the refrigerator group.

- Repair of tyres, such as re-grooving, re-treading or replacements.

- Repair of brakes with EBS diagnostics, pad or brake drum replacements

- Repair of doors, rolling doors and curtain repairs or replacements.