An LCV technical training event gives Gates the opportunity to expose a popular myth about the interchangeability of accessory drive belts.

The Citroen Berlingo and the Peugeot Partner Tepee are popular with fleets because the 1.6L DV6DTED diesel engines (2010+) have fuel-saving electromechanical drives (EMD). Whenever stop-start systems are on the agenda at a Gates Technical Workshop, therefore, the most frequently asked question is always:

Q. Is it OK to fit a standard accessory belt to a belt-driven Electromechanical Drive system?

The answer is simple: No, you cannot. The reasons why are a little more complex.

Emissions and solutions

Operators are employing more and more LCVs to solve urban distribution problems such as traffic congestion and tighter controls on engine emissions. Emission controls are set to get even tougher by 2020, when 95g CO2/km becomes the limit for all new passenger cars and light commercial vehicles fitted with similar engines.

Original Equipment (OE) drive systems manufacturers, such as Gates, work closely

with vehicle manufacturers to improve fuel efficiency and cut emissions. EMD stop-start systems are an important solution developed so far. Mechanics need to know how to address the relevant maintenance issues involved.

Principles of EMD

The 1.6L versions of the Peugeot Partner Tepee and the Citroen Berlingo are both fitted with the same type of EMD. It’s a collaborative design that involved Gates and another OE component manufacturer. It allows starter-generator systems to use an advanced belt drive for a smooth and almost completely silent vehicle start-up.

At start-up, cold engines require more cranking power than a warm one, so a conventional starter motor is used. At ideal operating engine temperatures, less cranking power is required for the re-start. Instead of using the starter motor to rotate the crankshaft, the crankshaft is rotated by means of the generator/alternator via the EMD system’s stop-start belt.

Belt strength

There are technical complexities to overcome. When the crankshaft is providing power to the alternator, the Right Hand Side (RHS) of the drive belt is taut, while the Left Hand Side (LHS) is slack. When the EMD draws power directly from the alternator, the tension is on the opposite side of the drive system. The RHS is slack, while the LHS is taut.

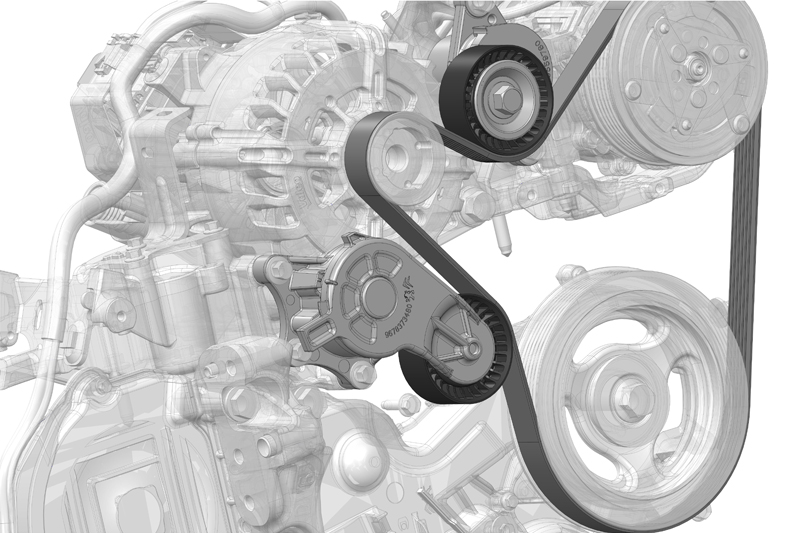

The EMD employs a specialist belt- driven two-tensioner system that can control the level of tension exerted on both sides of the drive system. This ensures that they can operate safely in the starting mode and in the power-generating mode.

Torque and strength

These EMDs deliver far greater degrees of belt tension than standard accessory belts. That’s why EMD belts use aramid cords to strengthen the belt, rather than traditional polyester cords.

Maintenance issues

The consistency and reliability of the two- tensioner EMD system is such that there are no specified replacement intervals. The interconnectivity of the parts must be considered. An essential issue is that the two tensioners work together as part of a single drive system. Fault diagnoses are difficult. The possibility that a mechanic is addressing a symptom rather than the cause of the problem is likely.

At replacement, Gates recommends that both tensioners are changed at the same time and that a new EMD belt is installed. Fitting a Gates belt kit is a good policy because it ensures that all parts required for the overhaul are correct, compatible and included in the same box. Gates Micro-V Stop & Start belts, for EMDs, such as these, are engineered for at least 600,000 starts.

Answer to the FAQ

A standard accessory belt will fail very quickly. More strength is required to cope with far greater degrees of tension and torque in the EMD. That’s why the construction of an EMD belt is so different from standard accessory belts. Aramid is much stronger than polyester.

If the belt fails, debris from the accessory drive has been known to contaminate the timing belt drive with disastrous consequences. Catastrophic engine damage is likely.