The reduction in noise, vibration, and harshness play a big part in the design of light commercial vehicles (LCVs). febi discusses the importance of ensuring this is kept on top of throughout a vehicle’s service life.

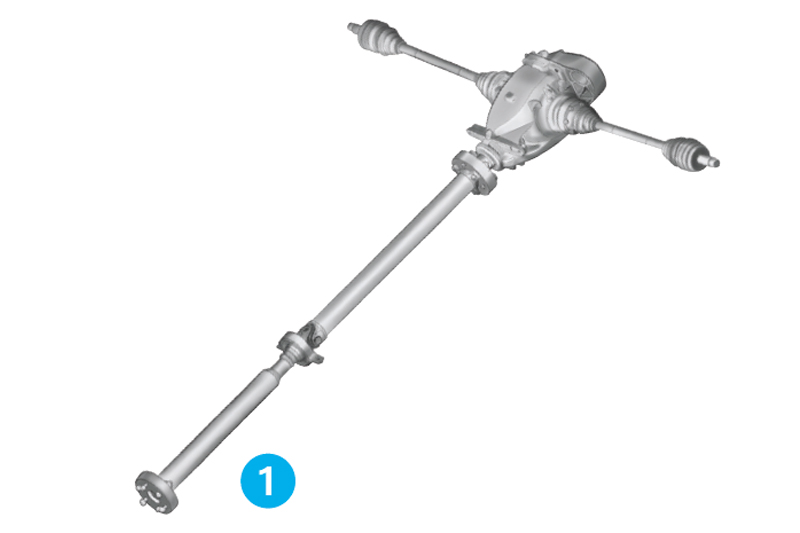

Ironing out squeaks, rattles, and vibrations throughout the vehicle increases driver and passenger comfort and reduces stress on the vehicle’s components. This includes the vehicle’s drive train. LCVs equipped with rear-wheel drive transmit power from the engine through the transmission to the axle with a prop-shaft (Fig. 1).

During its operation, this will alter in angle relative to the gearbox and final drive due to changes in the road surface that deflect the vehicles suspension system as it rotates. Unless a universal joint is fitted to each end of the prop shaft, it will bend and fracture.

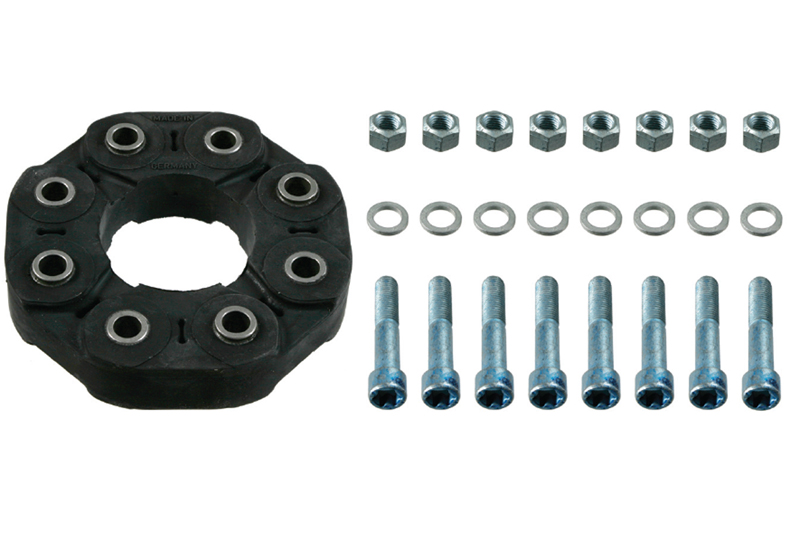

One solution is the flexible disc prop-shaft coupling (also known as a universal joint or giubo or doughnut coupling). It is a reinforced flexible rubber disc that connects the transmission output flange to the prop-shaft input flange. In some designs, due to high torsional demands, another flexible rubber disc is fitted to the prop-shaft output flange that connects to the final drive flange.

The flexible disc absorbs drive train vibration and backlash. All of the engine’s torque must be transmitted through the flexible disc before running through the driveshaft, differential axles and finally to the wheels. This flexible coupling joint design absorbs impact and shock forces to reduce drivetrain disturbances and prevent angular misalignment. This greatly reduces noise, vibration, and harshness from the drive train.

Like most LCVs, the flexible disc endures a tough life; therefore, it should be inspected during regular service intervals. If any deterioration of the flexible disc is noticed, this could result in some common symptoms that include driveline vibration, which may increase in intensity under acceleration and/or driveline thumping.

On inspection, it should be checked for cracks, tears, missing pieces, or distortion of the flexible disc. Any cracking or bulging indicates a failing flexible disc, and a replacement should be planned. When replacing any flexible disc, especially one driven to the point of destruction, you should inspect the prop-shaft centering guide bush, mating surfaces, and the bolt hole bores and threads. If any of these are worn, the shaft may still vibrate after replacing a new flexible disc.

In view of a replacement of a failing prop-shaft coupling, the replacement part’s design and construction needs to be considered. A prop-shaft flexible disc is constructed of cord reinforced rubber with metal inserts for the retaining bolts to go through from either side of the mating flanges to create a very strong and flexible joint.

This component’s properties must have good damping of torque peaks in the drivetrain and compensation of radial, axial, and angular misalignment, as shown in Fig. 2a and 2b. The benefits of this are stiffness that can be compensated in all directions and are resistant to shock-type stresses to give a long service life.

A sectional view of a febi bilstein flexible disc shows a very high number of cords and consistent reinforcement to withstand the torsional stresses that this component has to endure (Fig. 3).

Fig. 4 shows a sectional view of the cord reinforced rubber coupling, viewed on the drive section. This shows the compressed cord packages centred and aligned, making this a very strong and durable coupling.

Along with this, Fig. 5 shows a view of the overrun sections of the cord reinforced rubber coupling. Sectional views from a competitor’s product (Fig. 6 & 7) show very little cord reinforcement and inconsistent alignment; this would lead to a very short service life and the non-control of the high torsional stresses required of this component.

When replacing the flexible disc or discs (subject to vehicle application), they may have a marked alignment or have direction markings; please ensure correct fitment to ensure the disc’s correct operation. It is also recommended that the fixing bolts are replaced, subject to the manufacturer’s recommendation. Ensure all bolts are correctly tightened to the vehicle manufacturer’s specification.

All febi flexible discs are manufactured by OE supplier SGF, the global market leader in the automotive sector, ensuring maximum reliability, comfort, and first-time fit. The febi range includes parts for many popular LCVs on UK roads.

This includes febi No. 34961 to fit the Ford Transit (2013-) and 21199 to fit the Mercedes Sprinter (2006-). As part of the company’s commitment to bring new parts to the range, febi no. 175750 to fit the Iveco Daily (2014-) and 175754 to fit the VW Crafter (2016-) will be coming to the range soon.