Gates details its series of webinars that strive to keep fleet engineers and workshop managers abreast of all the latest opportunities to control the service, maintenance, and repair of their light commercial vehicles.

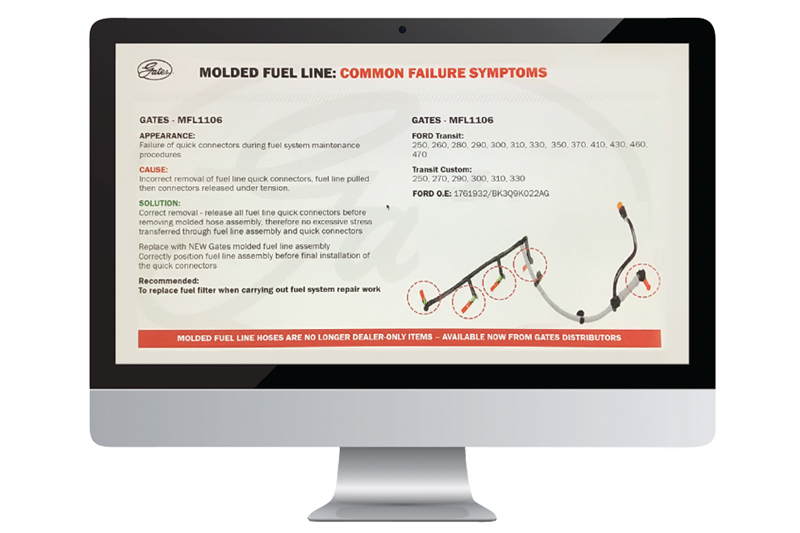

Delegates to the recent Fuel Line Solutions webinar from Gates heard that, when individual quick connectors and parts of Molded Fuel Line Hose assemblies are disconnected (for example, in order to carry out maintenance on adjacent parts), it can create potential premature parts failures. However, they also learned about an alternative source of replacement parts than more conventional OE supply routes.

Fuel line evolution

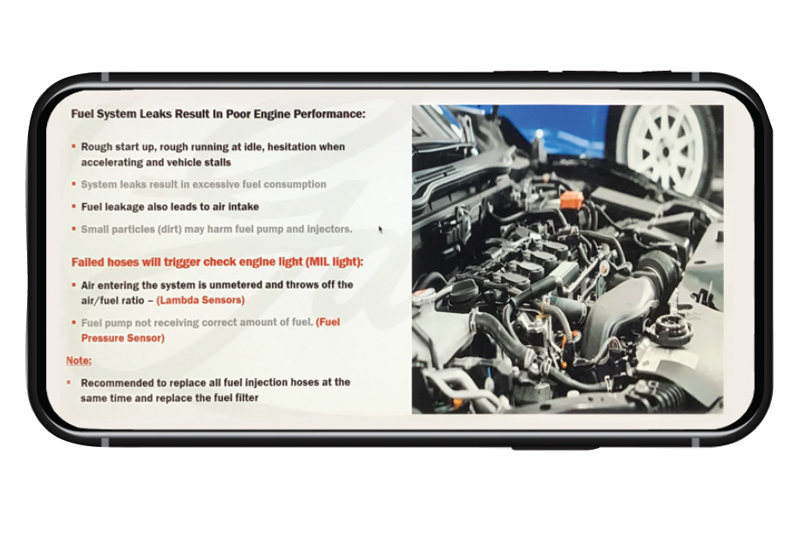

Most of the latest light commercials that are equipped with internal combustion engines have integral Moulded Fuel Line Hose assemblies. These have been designed for eventual replacement as single units from an OE source. Typically, the replacement procedures involved are not complex and little technical support is required. What workshops do need is guidance that relates to the disconnection and reconnection of these units during routine maintenance.

This is because over time, the OE connectors become brittle through exposure to high temperatures. The seals on the connectors are often damaged as a result of an incorrect disconnection procedure. Statistics show that the Ford Transit, Mercedes Sprinter, and Renault Trafic are typical examples from the light commercial vehicle parc that require extra attention in order to avoid future problems.

Avoidable errors

In each of these cases, irreparable damage to the quick connectors takes place as a direct result of first pulling the fuel line, then releasing any one of the connectors. The correct procedure is to release all of the quick connectors first, before attempting to remove the Molded Fuel Hose assembly unit. This simple adjustment to the procedure is an avoidable error that eliminates the transfer of any stress from the assembly unit on to the quick connectors, which may crack and subsequently fail during either the disconnection or reconnection procedure.

Cooling system developments

A forthcoming webinar from Gates will look at Cooling Systems and Critical Solutions. Most modern cooling systems feature application-specific Modular Cooling Hoses. These are cooling hose assemblies with one or more components that branch off at a variety of angles in order to accommodate engine design and the constraints of space inside the compartment.

These branches often include sensors and always feature quick connectors, o-rings, retaining clips and seals. As with fuel line assembly units, these cooling system assemblies are designed for eventual replacement as single units from an OE source. And like fuel systems assemblies, common failures are often related to internal temperatures, vibration and damage during routine maintenance procedures. Typical failures in the light commercial parc include Ford Transit, Fiat Ducato, and Peugeot Boxer.

Game-changing opportunities

As well as delivering solutions to maintenance problems such as fuel systems and cooling systems, fleet engineers and workshop managers are realising that Gates has some new OE quality product ranges that can provide better ways to control SMR costs.

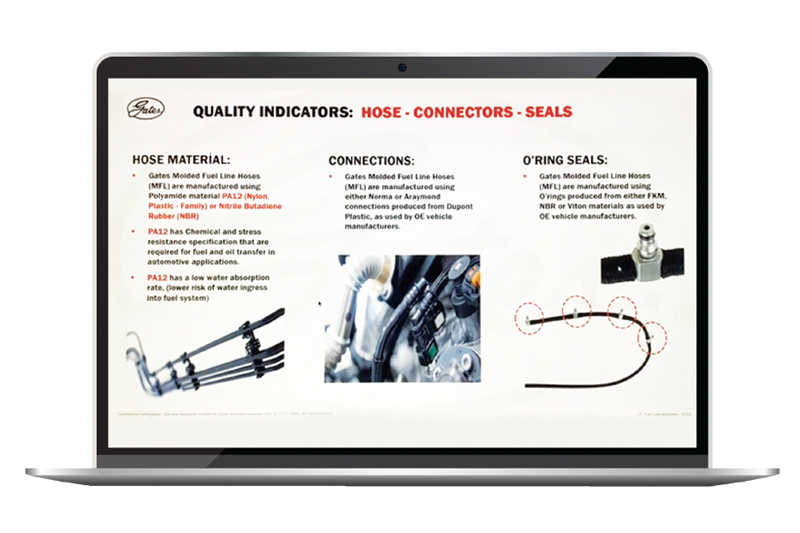

When it comes to Molded Fuel Line Hose assembly units and Modular Cooling Hoses, Gates provides one of the few alternative sources to the conventional and more expensive OE supply route. In 2021 alone, 60 new part numbers were added to the range. These include references for light commercials such as the aforementioned Ford and Citroen models, as well as other light commercials such as Citroen Berlingo and Peugeot Expert. The total number of part numbers in the range that’s currently available in the UK is now 220.

On the cooling system side, Gates has added 330 Modular Cooling Hose part numbers this year, among them parts for light commercials manufactured by Ford, Mercedes-Benz and Renault included in a total range of nearly 3,000.

The realisation that significant parts ranges for fuel and cooling systems assembly units are no longer ‘Dealer Only’ items and that they are supplied by Gates, a hose manufacturer and a supplier with an established OE pedigree, is an SMR game-changer for many end-users. It means these parts can be reliably sourced with confidence at more competitive prices from a supplier that enjoys a preferred supplier status for various systems, and on vehicles built by a wide range of manufacturers of cars, trucks, and buses.