Highways England reportedly estimates that 20% of breakdowns are directly related to flat or under inflated tyres. TyreWatch believes that this percentage can be significantly reduced and, in some cases, negated by careful tyre management.

According to TyreWatch, tyre management requires preventative maintenance, and the nature of tyres means that preventative maintenance is only effective if problems are identified before they occur, so that pre-emptive action can be taken.

There are numerous systems on the market that will indicate when a puncture has occurred, but this information is of little use, as by the time the vehicle has a puncture, the dreaded downtime has already begun. A system that can predict when a puncture or a blow-out is about to occur, giving the workshop time to schedule preventative maintenance, will virtually negate downtime caused by tyre pressure problems.

Predictive Tyre Monitoring

TyreWatch PTM (Predictive Tyre Monitoring) is a real-time tyre monitoring system for commercial vehicles. It has been operating for 18 months and it is now a leading player in independent commercial vehicle PTM by virtue of its robust, economical and flexible solution.

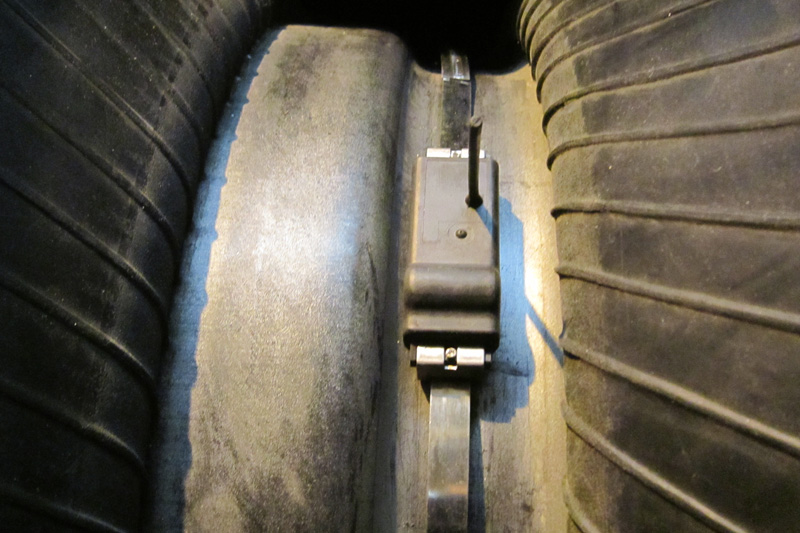

Tyrewatch PTM consists of sensors inserted inside each wheel rim, a display screen in the cab, and a GPS box which transmits real time tyre and location information via the mobile telephone network. Not only is the driver able to see the tyre pressures and temperatures, but they are uploaded to the web so they can be monitored by any device that has an internet connection.

The importance of the system is that it is proactive and will automatically generate two kinds of alert. The first is an urgent stop alert, which, in a similar vein to all TPMS, is activated if the system detects a rapid loss of pressure or a high temperature, allowing the vehicle to be pulled over in a controlled way preventing a blow-out. Obviously, in these cases, downtime will occur but, by preventing a tyre failure, this can be kept to a minimum.

A maintenance alert is activated when a non-urgent event occurs – such as a loss of pressure due to a leaky valve or a modest rise in temperature due to a mechanical fault on the axle. There is no alarm in the cab to worry the driver but an automatic alert is sent via SMS or email to the vehicle operator and tyre provider. This type of fault is minor, so the vehicle can continue on its journey. The automatic maintenance report means that preventative maintenance can be scheduled before the vehicle returns to base.

TyreWatch PTM has all the same benefits to fleet operators as TPMS, including improved fuel consumption, tyre life and safety. The big difference, however, is its ability to predict problems before they occur and communicate them in real time, so that the workshop can manage by exception.

The importance of this to the workshop is that it makes scheduling of maintenance more efficient. The maintenance report informs the workshop of the issues before the vehicle arrives, and technicians can concentrate on the problem without having to spend valuable time investigating. Tyrewatch PTM can add value to R&M contracts as it is not linked to a particular tyre manufacturer and so it does not matter what tyre policy a potential client uses, and it can be added to the monthly R&M cost.